By Sarah Jenkins

Published: October 24, 2024

Location: Detroit, Michigan

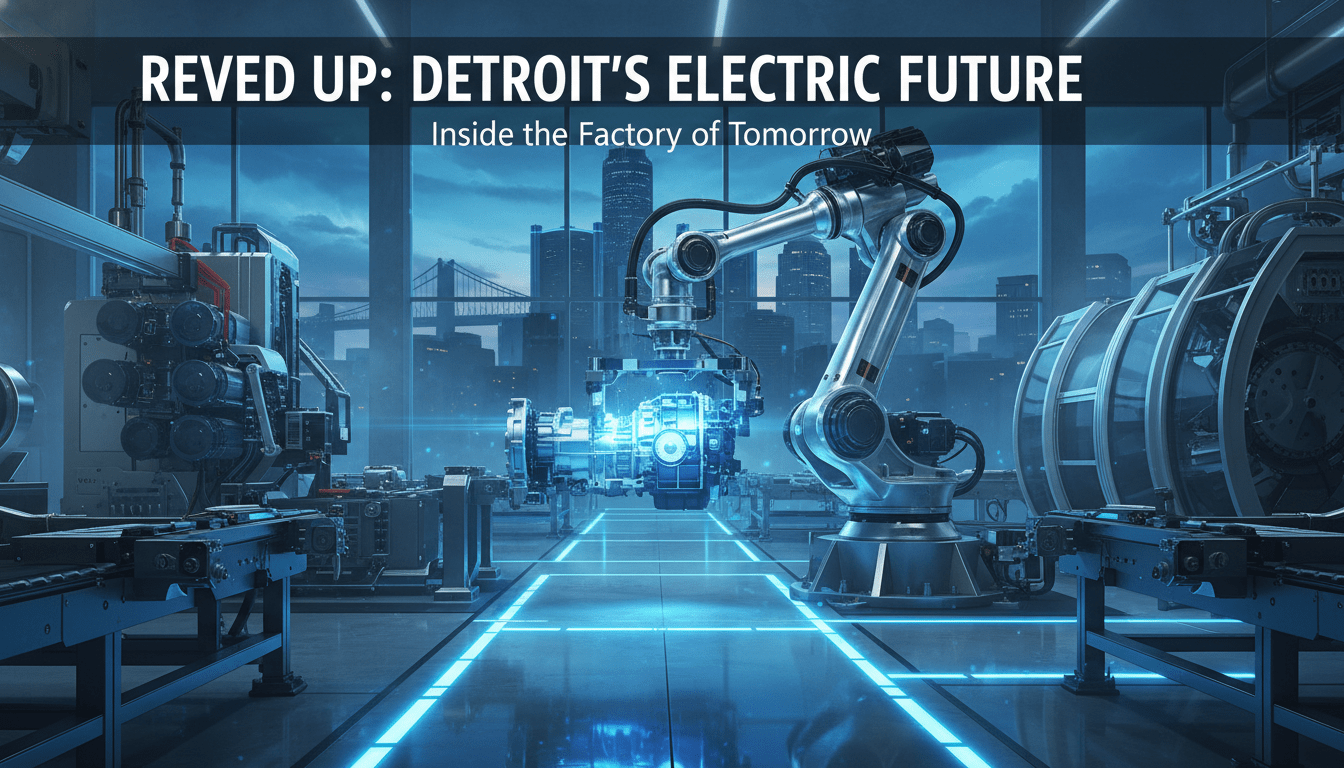

Detroit Leads the Charge in Electric Drivetrain Technology

For over a century, the identity of Detroit has been inextricably linked to the internal combustion engine. The roar of a V8 was the soundtrack of the city’s industrial might. Today, however, the Motor City is tuning into a new frequency: the quiet, high-torque hum of electric drivetrain technology. As the global automotive industry pivots toward sustainability, Detroit is positioning itself not just as a participant, but as the primary architect of this technological revolution.

The Shift to Battery-Electric Systems

The transition from traditional powertrains to electric drivetrains represents the most significant manufacturing shift in automotive history. Unlike internal combustion engines, which rely on thousands of moving parts, electric drivetrain technology centers on three core components: the high-voltage battery pack, the inverter, and the electric motor.

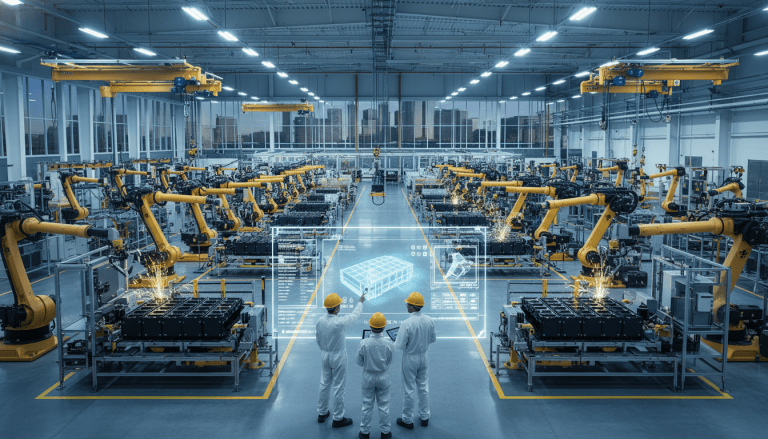

Major local players are heavily investing in this simplification and electrification. According to the Michigan Economic Development Corporation (MEDC), billions of dollars have been committed to retrofitting assembly plants across Southeast Michigan to accommodate EV production. General Motors’ Factory ZERO, straddling the Detroit-Hamtramck border, stands as a testament to this shift, serving as the launchpad for the company’s Ultium battery platform.

“The engineering required for electric drivetrains is fundamentally different,” said a spokesperson for a Tier 1 automotive supplier based in Troy. “We are moving from mechanical complexity to software-defined efficiency. Detroit is rapidly becoming a hub for the electrical engineering talent needed to drive this change.”

Impact on Detroit Residents

For the people of Detroit, the rise of electric drivetrain technology brings both promise and uncertainty. The immediate impact is visible in the local labor market. As assembly lines change, the skills required to work on them change as well.

Local workforce development agencies report a surge in demand for certifications related to high-voltage systems and robotics. This evolution is vital for preserving the Detroit labor market. While there are concerns that EVs require fewer workers to assemble than gas vehicles due to having fewer parts, the localization of the supply chain—specifically battery cell manufacturing—is creating new roles that didn’t exist a decade ago.

Residents living near manufacturing hubs are also eyeing the environmental benefits. A shift toward producing zero-emission vehicles aligns with city and state goals to reduce industrial carbon footprints, potentially improving air quality in neighborhoods that have historically borne the brunt of industrial pollution.

Background & Data

The urgency to master electric drivetrain technology is driven by federal mandates and global competition. Data from the U.S. Department of Energy indicates that battery costs have fallen significantly over the last decade, making EVs more price-competitive. However, the supply chain remains a critical battleground.

In the Detroit metropolitan area, the focus is not just on assembly, but on the vertical integration of the drivetrain. This includes:

- E-Axle production: Integrating the motor, transmission, and power electronics into a single unit.

- Thermal management: Developing systems to keep batteries at optimal temperatures during Michigan winters.

- Domestic sourcing: Reducing reliance on overseas minerals and components.

Reports suggest that Michigan has secured more than $16 billion in electric vehicle and battery manufacturing investments since 2015, solidifying the state’s role in the automotive sector.

What Happens Next

As 2025 approaches, the proliferation of electric drivetrain technology will accelerate. The “Big Three” automakers have set aggressive targets for EV sales volume by 2030. For Detroit, the next few years are critical. The city must ensure that its infrastructure—from power grids to charging stations—can support the very technology it produces.

The success of this transition will determine whether Detroit remains the automotive capital of the world or cedes ground to emerging tech hubs. Currently, with factories humming and R&D centers expanding, the city appears ready to lead the electric era.