In the sprawling assembly plants that define Detroit’s skyline, a quiet revolution is underway. While the roar of machinery has long been the soundtrack of the Motor City, the nature of that noise is changing. The integration of advanced robotics in Detroit auto manufacturing is moving beyond simple mechanical arms welding frames; it is evolving into a sophisticated ecosystem of artificial intelligence, collaborative robots (cobots), and data-driven efficiency that is fundamentally altering the local economy.

As the automotive industry pivots aggressively toward electric vehicle (EV) production, manufacturers like General Motors, Ford, and Stellantis are leaning heavily on automation to meet rigorous production targets. However, this technological leap brings with it complex questions regarding the future of the workforce in Southeast Michigan. While efficiency is skyrocketing, the conversation on the factory floor is shifting from assembly to oversight, requiring a new set of skills from Detroit’s storied labor force.

The New Era of Automation in the Motor City

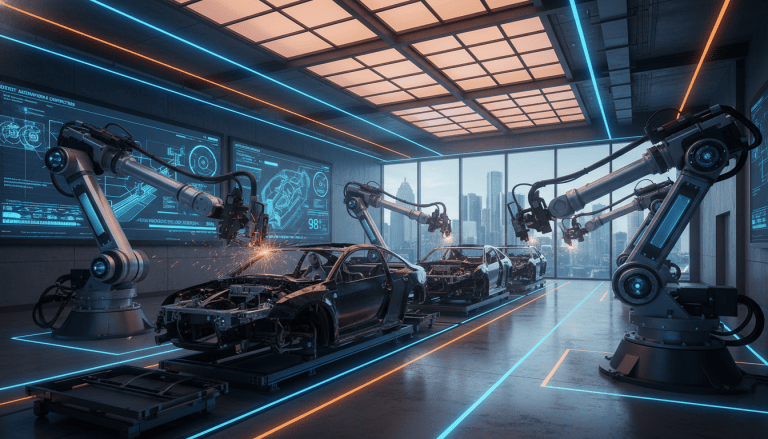

For decades, Detroit has been the global epicenter of industrial automation. Today, the technology being deployed is smarter and more adaptable than ever before. According to recent reports from the International Federation of Robotics (IFR), the automotive sector remains the largest adopter of industrial robots globally, with a significant concentration of these assets deployed in Michigan facilities.

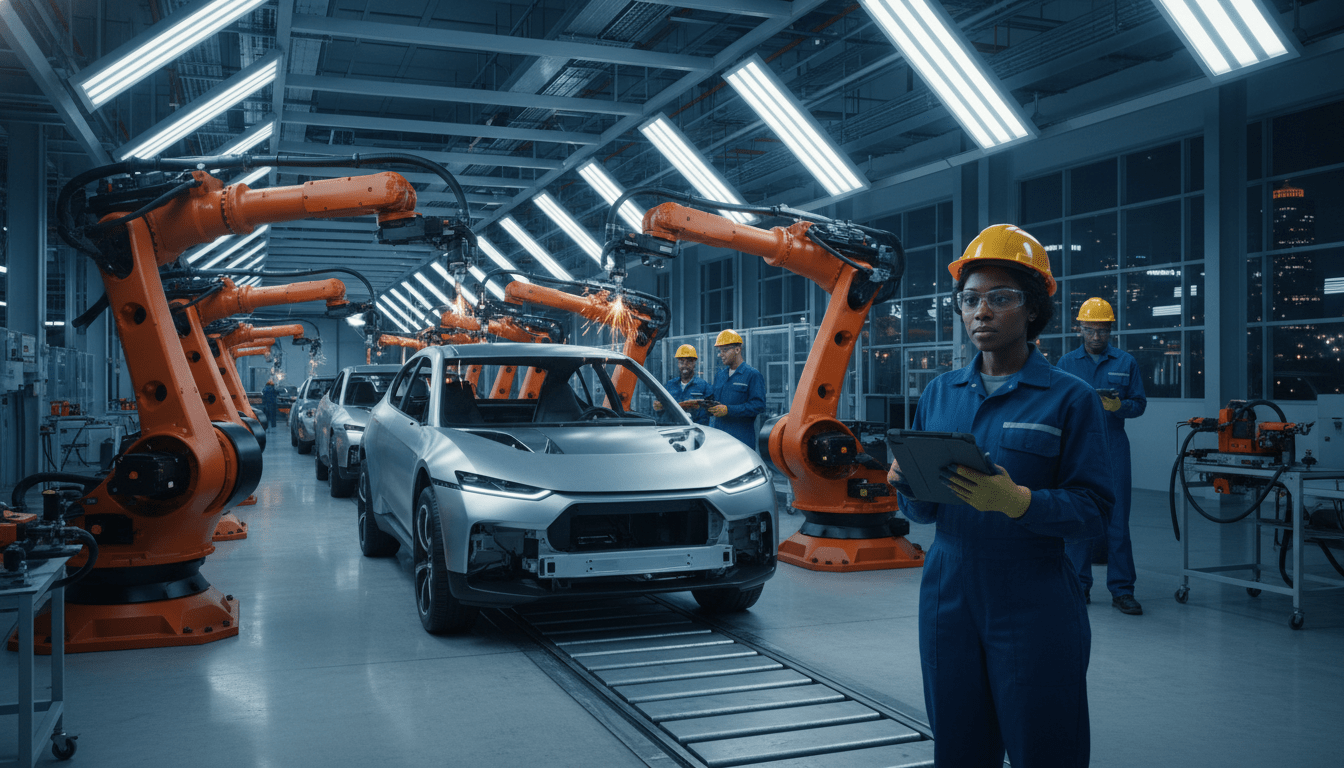

Modern factories, such as GM’s Factory ZERO regarding the Detroit-Hamtramck border, are showcasing how robotics in Detroit auto manufacturing is utilized not just for heavy lifting, but for precision tasks. “Cobots”—robots designed to work safely alongside humans—are becoming commonplace. These machines handle ergonomically difficult tasks, such as overhead installation or handling hazardous materials, reducing injury rates among human workers.

Industry experts note that the shift to EV platforms has accelerated this trend. Electric vehicles require fewer moving parts than internal combustion engines, but the battery assembly process requires a level of precision and weight handling that is ideally suited for automation. This transition is driving billions of dollars in capital investment into Detroit-area plants, modernizing infrastructure that in some cases dates back nearly a century.

Impact on Detroit Residents and the Workforce

For the residents of Detroit, the surge in automation is a double-edged sword that sparks both hope and anxiety. On one hand, the efficiency gains help secure the long-term viability of the Big Three in a competitive global market, theoretically protecting the region’s economic anchor. On the other hand, there is a persistent fear that robotics in Detroit auto manufacturing will lead to job displacement.

However, local labor data suggests a shift in job descriptions rather than a simple erasure of headcount. “The narrative that robots are taking all the jobs isn’t entirely accurate in the current context,” says a representative from a local workforce development agency. “What we are seeing is a desperate need for robotics technicians, maintenance crews, and software operators. The job is moving from holding a wrench to holding a tablet.”

For local families, this means the pathway to a middle-class life in the auto industry is changing. Entry-level assembly jobs are becoming more technical. This shift has prompted a rise in enrollment at institutions like Wayne County Community College District, where specialized programs are designed to upskill workers for the automated age. Residents willing to engage in retraining are finding themselves in high demand, often at higher wage brackets than traditional assembly roles.

For more on the shifting local job market, read our coverage on Detroit’s evolving employment landscape.

Background & Data: Michigan’s Automated Advantage

The numbers back up the visual changes on the factory floors. Data from the Association for Advancing Automation indicates that North American companies ordered record numbers of robots in recent years, with the automotive OEMs (Original Equipment Manufacturers) driving a substantial portion of that demand. Michigan continues to lead the nation in robot density—the number of robots per 10,000 workers.

Historically, automation spikes coincide with new model launches. With the industry-wide push for EVs, the retooling of plants is happening simultaneously across the metro area. For example, the transformation of the Jefferson North Assembly Plant involves state-of-the-art flexible manufacturing systems that allow the line to switch between different vehicle models seamlessly—a feat made possible only through advanced robotics.

According to the U.S. Bureau of Labor Statistics, while manufacturing employment has seen fluctuations, the sector for industrial machinery maintenance has seen steady growth. This suggests that the capital investment in robotics in Detroit auto manufacturing is creating a secondary economy of service and support that is vital to the region.

Looking Ahead: The Factory of the Future

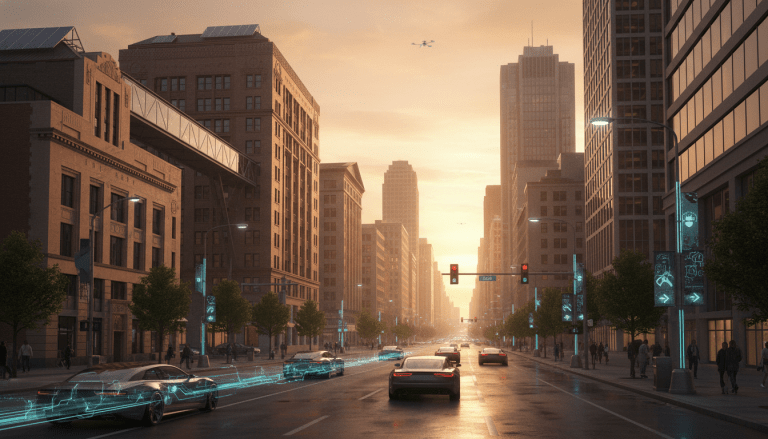

What happens next for Detroit? The consensus among industry analysts is that the integration of AI will be the next frontier. Robots will not just repeat programmed tasks but will use machine learning to optimize workflows in real-time, predict maintenance needs before a breakdown occurs, and manage supply chains autonomously.

For Detroit City, this means the definition of a “blue-collar” town is getting an update. The city is increasingly becoming a hub for mechatronics and engineering. Local startups and tech firms are springing up to service the massive automated infrastructure of the Big Three, creating a ripple effect that benefits the broader Detroit economy.

As the industry hurtles toward 2030, the success of robotics in Detroit auto manufacturing will likely be measured not just by production quotas, but by how well the region prepares its people to work alongside their new mechanical colleagues. The machines are here to stay, and for Detroit, mastering them is the key to remaining the automotive capital of the world.