By Marcus Thorne

Published: October 26, 2023

Location: Detroit, Michigan

Detroit’s Industrial Renaissance: How Advanced Manufacturing is Reshaping the Motor City

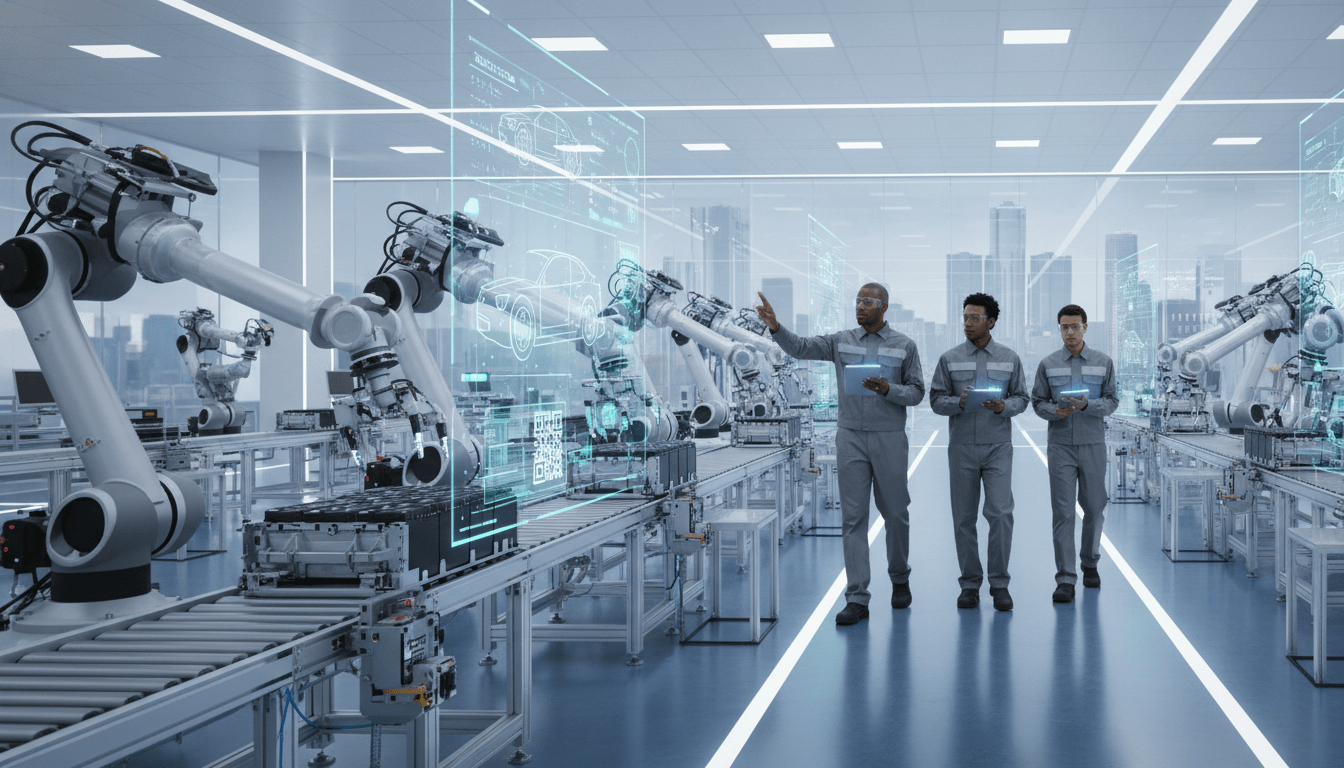

For decades, Detroit was synonymous with the assembly line—a place where steel was stamped and engines were forged through sheer mechanical force. Today, however, the Motor City is undergoing a quiet but profound transformation. The factory floors of Detroit are becoming high-tech laboratories, driven by the rapid adoption of advanced manufacturing in Detroit. This shift toward “Industry 4.0″—the integration of automation, data exchange, and artificial intelligence in manufacturing technologies—is positioning the region as a global leader in tech-driven production.

While the automotive sector remains the anchor, the methods of production are evolving. Local manufacturers are increasingly relying on 3D printing, collaborative robots (cobots), and digital twins to optimize efficiency. This technological pivot is not just about keeping up with global trends; it is about securing Detroit’s economic future in a digital age.

The Shift to Smart Factories

The integration of technology into manufacturing processes is visible across the metro area. According to Automation Alley, Michigan’s Industry 4.0 knowledge center, the state is home to one of the highest concentrations of engineering talent in the country. Their initiatives, such as Project DIAMOnD, have distributed 3D printers to small manufacturers across the region, creating a decentralized manufacturing network capable of pivoting production at a moment’s notice.

“We are seeing a fundamental change in how things are made,” said a representative from a Detroit-based robotics integration firm. “It is no longer just about horsepower; it is about computing power. The factories opening in Detroit today look more like server rooms than the foundries of the past.”

This surge in Detroit Auto & Business innovation is heavily tied to the electric vehicle (EV) transition. As major automakers retool their plants for EV production, they are implementing advanced sensors and AI-driven quality control systems that require a sophisticated infrastructure.

Impact on Detroit Residents

For the average Detroit resident, the rise of advanced manufacturing in Detroit presents both a challenge and an opportunity. The days of walking into a factory with a high school diploma and securing a lifelong job on the line are fading. In their place, however, is a growing demand for skilled technicians who can manage robotics, analyze data, and maintain complex digital systems.

This shift requires a workforce ready to upskill. Local organizations and community colleges are stepping up to bridge the gap. Programs focused on mechatronics and digital literacy are becoming essential.

“The jobs are here, but the requirements have changed,” noted a workforce development coordinator at a local non-profit. “We are working to ensure that Detroiters from all neighborhoods have access to the training needed to operate these new machines. This isn’t just for engineers; it’s for operators who need to understand the digital interface of a modern assembly line.”

For residents, this means higher potential wages. Tech-driven manufacturing roles typically pay more than traditional assembly jobs, offering a pathway to the middle class for those willing to engage with the new technology.

Background & Data

Data from the Michigan Economic Development Corporation (MEDC) supports the narrative of growth. Michigan ranks among the top states for manufacturing jobs, but the composition of those jobs is shifting. Investments in the EV supply chain alone have brought billions of dollars into the state over the last few years.

Furthermore, a report by the Workforce Intelligence Network highlights a sustained demand for computer-controlled machine tool operators and industrial engineering technicians in Southeast Michigan. This data suggests that the sector is resilient, provided the talent pipeline remains robust.

The Role of LIFT

Another key player is LIFT, the Detroit-based national manufacturing innovation institute. LIFT operates a “learning lab” in the city designed to prepare students and workers for advanced manufacturing careers, proving that the infrastructure for learning is being built alongside the factories themselves.

What Happens Next

Looking ahead, the convergence of local tech developments and traditional manufacturing will likely accelerate. With the continued push for autonomous vehicles and green energy solutions, Detroit’s factories will need to become even smarter.

The success of advanced manufacturing in Detroit will depend on continued collaboration between the public sector, private industry, and educational institutions. If successful, Detroit will not only retain its title as the Motor City but will redefine what it means to be a manufacturing capital in the 21st century.