By Sarah Jenkins

Published: October 24, 2023

Location: Detroit, Michigan

Robotics Revolution: How Automation is Reshaping Detroit’s Auto Plants

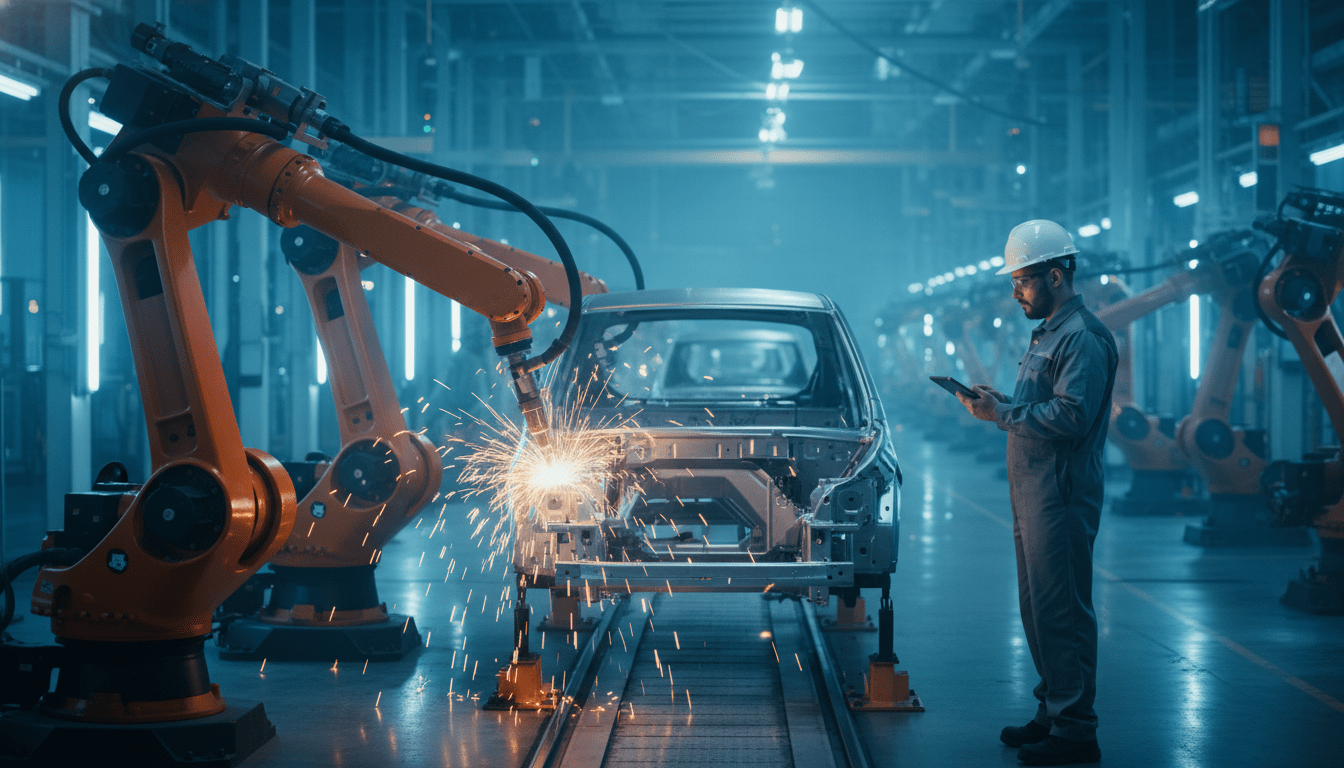

The rhythmic clatter of Detroit’s historic assembly lines is being harmonized with a new sound: the silent precision of advanced automotive robotics. As the Motor City accelerates its transition toward electric vehicle (EV) production, the factory floor is undergoing its most significant transformation in decades. From General Motors’ Factory ZERO to the Stellantis Mack Assembly Complex, automation is not just changing how cars are built—it is redefining the local economy.

While the integration of robots in manufacturing is not new, the sophistication of today’s machines is miles ahead of the rigid robotic arms of the past. The latest wave of automotive robotics involves AI-driven collaborative robots, or "cobots," designed to work safely alongside human operators, a shift that industry experts say is crucial for the complex assembly required by modern EVs.

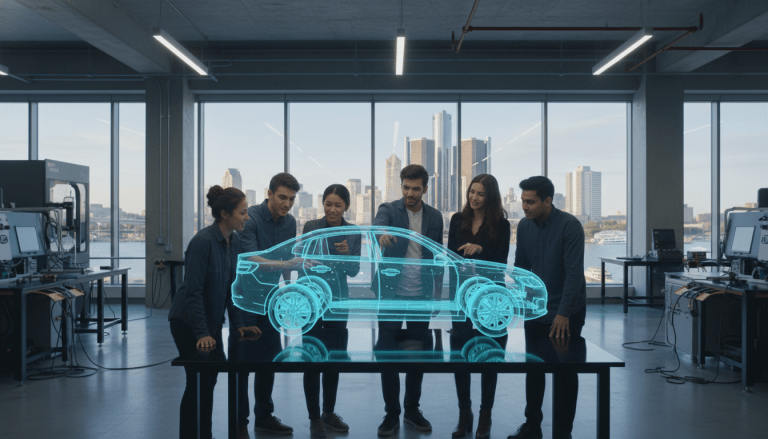

The Shift to Smart Manufacturing

According to data from the International Federation of Robotics (IFR), the automotive industry remains the largest adopter of industrial robots globally. In Detroit, this trend is visible in the massive retooling efforts undertaken by the "Big Three." These smart factories utilize interconnected systems where robots communicate with central servers to optimize efficiency in real-time.

"The perception of a robot taking a job is evolving into a robot aiding a worker," said Mark Davis, a manufacturing analyst based in Southeast Michigan. "In facilities like the Rouge Electric Vehicle Center, automation handles the heavy lifting and high-precision tasks, allowing human workers to focus on quality control and complex decision-making processes that machines simply cannot replicate."

Impact on Detroit Residents and Jobs

For Detroit residents, the surge in local jobs and employment opportunities is a mix of promise and challenge. The fear that automation will displace human labor is a historical constant in the auto industry. However, local workforce development data suggests a shift in the type of labor demanded rather than a simple reduction.

Local educational institutions and trade unions are ramping up programs to upskill workers. "We aren’t just looking for assembly line workers anymore; we are looking for robotics technicians, system operators, and maintenance staff who can keep these machines running," noted a representative from a Detroit-based workforce development agency.

This transition means that while some traditional manual roles may diminish, higher-paying technical roles are emerging. For the Detroit economy, this underscores the urgent need for accessible technical education to ensure that long-time residents can participate in this new industrial era.

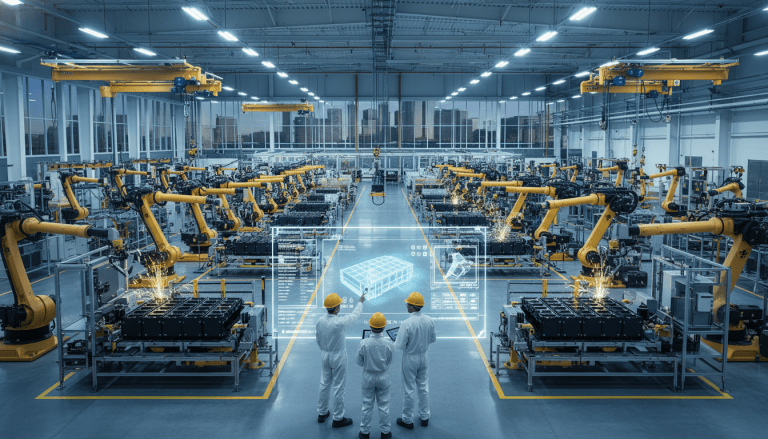

Background & Data: The Investment Boom

The pivot to automation is backed by billions in investment. Recent reports indicate that the operational stock of robots in the U.S. automotive sector hit a new record high last year. This surge is directly correlated with the push for electrification.

- Investment Scale: Billions allocated by GM and Ford for plant retooling in Michigan.

- Robot Density: The U.S. auto industry has one of the highest densities of robot usage in the world.

- Efficiency Gains: Automated systems have reduced the time-to-market for new EV models significantly.

For further reading on how these investments affect the city’s infrastructure, check our coverage on Detroit development projects.

What Happens Next

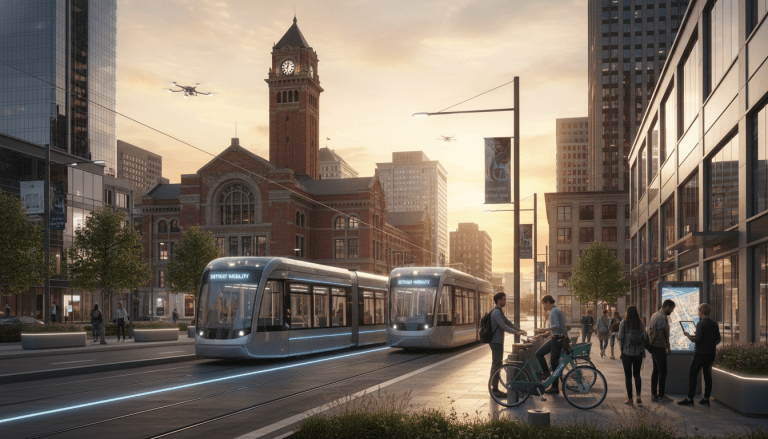

As artificial intelligence continues to mature, the next generation of automotive robotics will likely be even more autonomous, capable of predictive maintenance and self-correction. For Detroit, the challenge remains balancing technological advancement with social responsibility.

The city stands at a crossroads: it can become the global hub for high-tech manufacturing talent, provided the bridge between current workforce skills and future factory requirements is built strong enough. As 2025 approaches, the eyes of the manufacturing world remain firmly fixed on Detroit.