Detroit is currently undergoing one of the most significant technological transformations in its history, shifting from traditional assembly lines to highly integrated networks of data and machinery. At the heart of this revolution are cyber-physical systems in Detroit, a technology that bridges the gap between the virtual world of algorithms and the physical world of manufacturing.

While the term “cyber-physical systems” (CPS) might sound academic, its application is rapidly reshaping the local economy. These systems integrate computation, networking, and physical processes—essentially allowing computers and robots to communicate in real-time to optimize production, manage traffic, and even improve energy grids. As the automotive industry pivots toward autonomous and electric vehicles, Detroit is positioning itself as the global command center for this “Industry 4.0” technology.

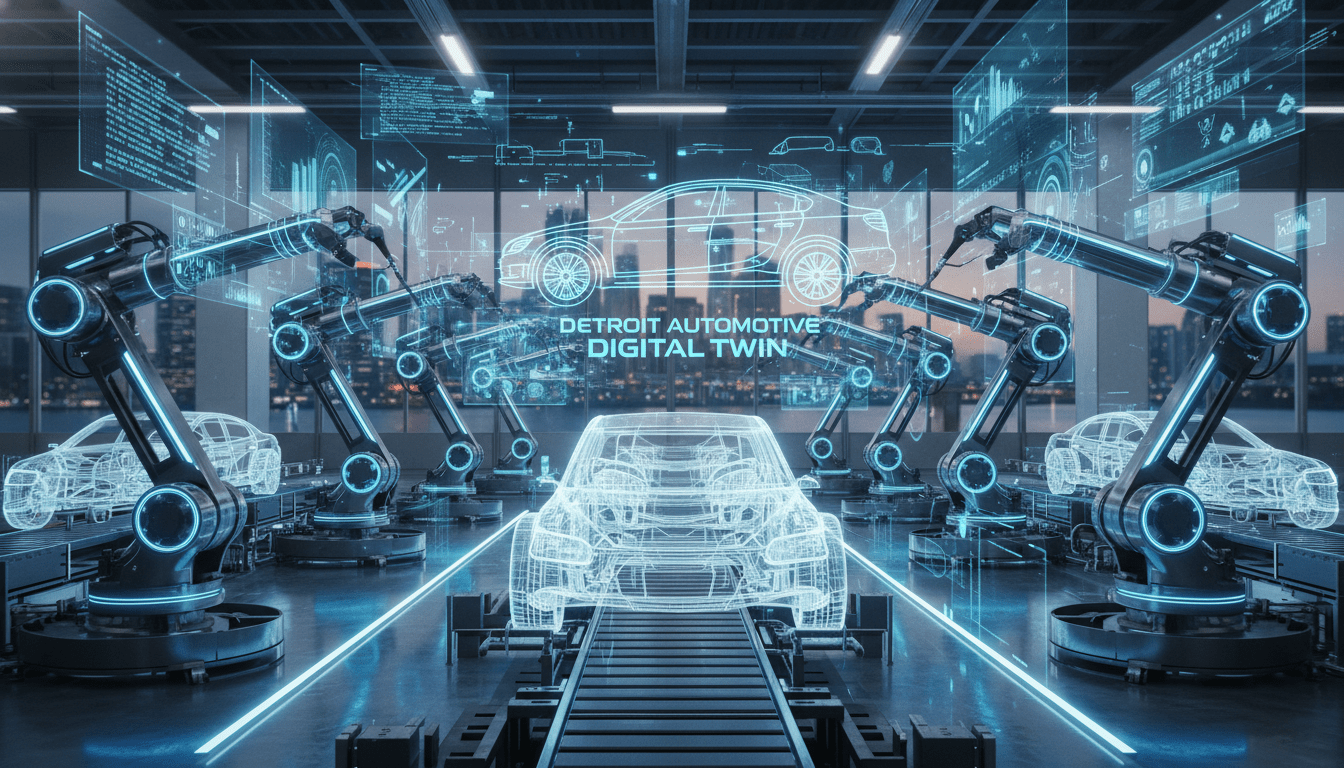

The Convergence of Digital and Physical Manufacturing

For decades, Detroit has been defined by its ability to bend steel. Today, the region is defined by its ability to generate and process data. Cyber-physical systems function as the nervous system of modern factories. According to data from the Automation Alley, Michigan’s Industry 4.0 knowledge center, the integration of these systems is crucial for small and medium-sized manufacturers to remain competitive globally.

“We are seeing a fundamental shift where the factory floor is no longer just about mechanics; it is about the continuous flow of information,” said a representative from a local Tier 1 automotive supplier. “Digital twins—virtual replicas of physical systems—allow us to test changes in a virtual Detroit factory before a single bolt is turned in the real one.”

This technology is already visible in major developments across the city. General Motors’ Factory ZERO and Ford’s Rouge Electric Vehicle Center utilize advanced cyber-physical systems to monitor equipment health, predict maintenance needs, and ensure quality control with a precision that human operators alone cannot achieve.

Impact on Detroit Residents and the Workforce

A primary concern for many Detroiters is what this technological shift means for jobs. The narrative often suggests that automation replaces human workers, but experts argue that the rise of cyber-physical systems in Detroit is creating a demand for a new type of skilled labor.

The implementation of these systems requires a workforce capable of managing complex interfaces. Instead of manual repetition, jobs are moving toward system monitoring, data analysis, and mechatronics maintenance. This shift presents both a challenge and an opportunity for the local workforce development sector.

“The skill gap is the biggest hurdle we face,” noted a workforce analyst during a recent regional economic forum. “We have the open positions, but we need to accelerate training programs that teach local residents how to interact with these cyber-physical environments. It is not just about coding; it is about understanding how digital tools control physical outcomes.”

Local institutions are stepping up to bridge this gap. Wayne State University and the University of Michigan have expanded their research and curriculum regarding cyber-physical systems, aiming to build a pipeline of talent directly from Detroit neighborhoods to high-tech manufacturing floors.

Beyond the Factory: Smart City Infrastructure

While manufacturing drives the conversation, the impact of these systems extends into the city’s infrastructure. Detroit’s push to become a “smart city” relies heavily on CPS technology. This includes intelligent traffic signals that adapt to congestion in real-time and smart grid technologies utilized by DTE Energy to balance power loads.

For the average resident, this means potentially shorter commute times and more reliable utilities. The Michigan Central innovation district in Corktown is serving as a living lab for these technologies, testing how sensors in the physical environment can communicate with connected vehicles to improve pedestrian safety and traffic flow.

Investment and Economic Outlook

The economic stakes are high. According to the Detroit Regional Partnership, the 11-county region is uniquely positioned to lead the nation in smart manufacturing due to its density of engineering talent. Federal funding and private investment are flowing into the region to support Detroit tech initiatives centered around CPS.

Initiatives like Project DIAMOnD (Digital, Independent, Agile, Manufacturing on Demand) have already distributed 3D printers and smart connections to hundreds of local manufacturers, creating a decentralized blockchain-connected network that proved vital during supply chain disruptions. This network effectively turns the region into one giant, connected factory.

Challenges of Cybersecurity

With increased connectivity comes increased risk. As physical systems become reliant on internet connectivity, they become vulnerable to cyberattacks. A hacked computer is a nuisance; a hacked robotic arm or autonomous vehicle is a physical danger.

“Security is the other side of the coin for cyber-physical systems in Detroit,” explained a cybersecurity consultant based downtown. “If we are going to connect our water systems, our power grids, and our assembly lines to the cloud, we must ensure that our cybersecurity infrastructure is as robust as our physical infrastructure.”

What Happens Next?

As 2025 progresses, Detroit continues to shed its “Rust Belt” image in favor of a “Smart Belt” identity. The integration of cyber-physical systems is not a distant future concept—it is the current operating reality for the city’s largest employers.

For Detroit, the path forward involves a delicate balance: aggressively adopting these high-tech systems to maintain global leadership in mobility while ensuring that the educational infrastructure keeps pace so that Detroiters are the ones filling these high-paying, high-tech roles. The successful integration of cyber-physical systems in Detroit will likely define the city’s economic trajectory for the next half-century.