By Alex Mercer

Published: October 14, 2025

Location: Detroit, Michigan

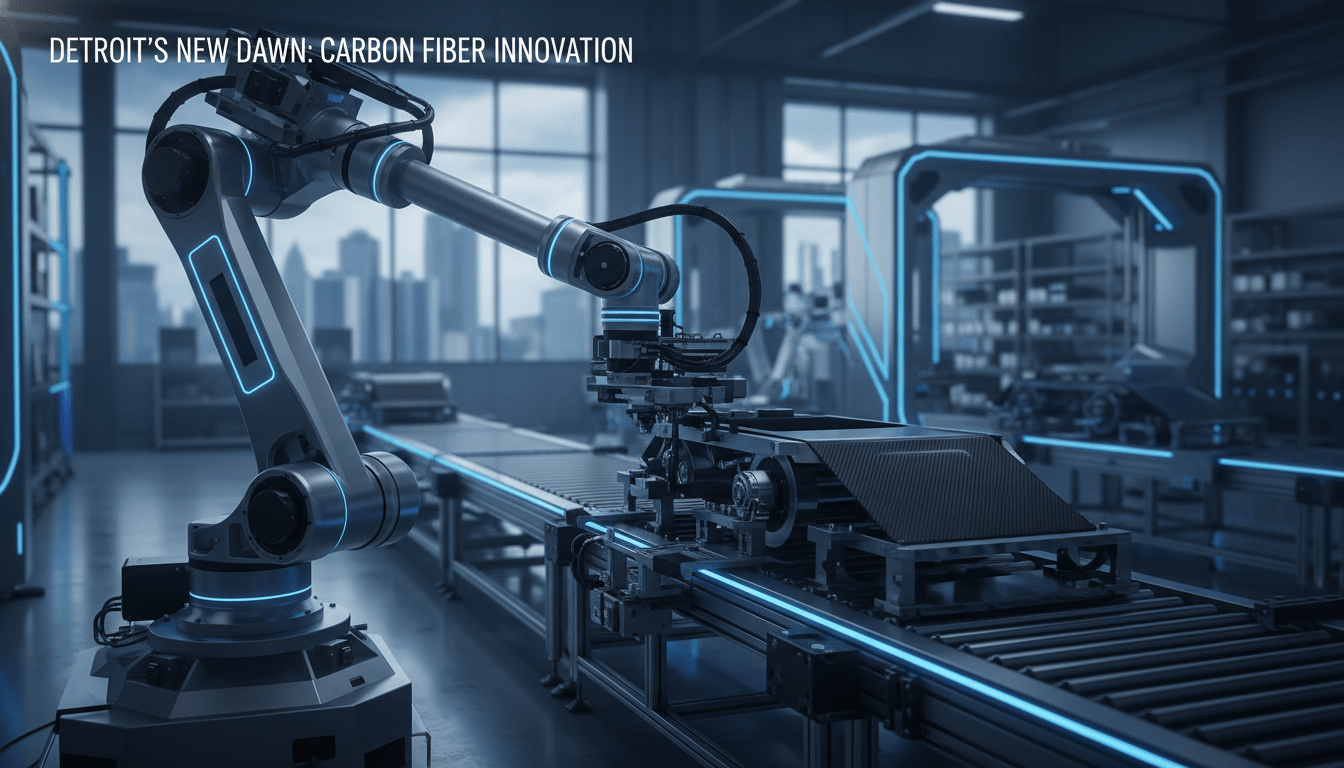

Detroit Leads Shift in Advanced Materials Manufacturing for Next-Gen Auto Industry

Detroit is no stranger to making things, but the substances being shaped in the city’s industrial corridors are undergoing a radical transformation. As the global automotive industry pivots almost entirely toward electrification, the demand for lighter, stronger, and more conductive materials has surged. Detroit is answering that call, positioning itself as a national hub for advanced materials manufacturing.

No longer defined solely by stamped steel and iron casting, the city’s manufacturing base is rapidly integrating carbon fiber composites, aluminum alloys, and next-generation battery components. This shift is not just a technological upgrade; it represents a fundamental economic evolution for Southeast Michigan, securing the region’s relevance in a post-combustion engine world.

The Evolution of the Motor City

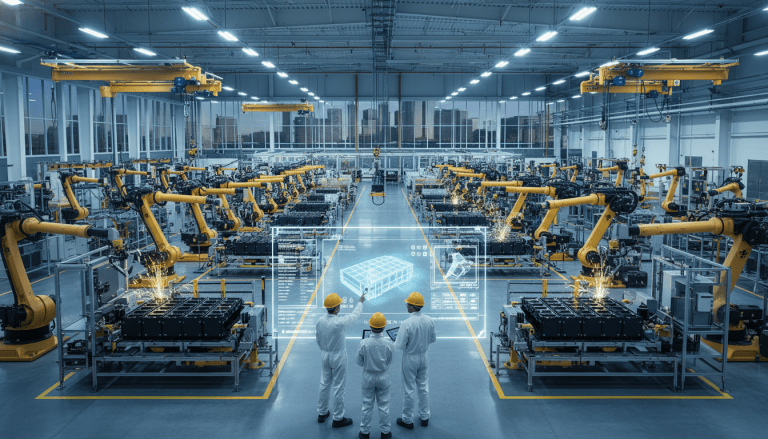

The driving force behind this transition is the physics of electric vehicles (EVs). Batteries are heavy, and to maximize range, automakers must shave weight from every other part of the vehicle. This necessity has turned Detroit into a testing ground for lightweighting technologies.

According to the Michigan Economic Development Corporation (MEDC), the state has seen a 15% increase in investments related to advanced materials research and production over the last three years. Facilities that once focused on traditional powertrain components are retooling to produce high-strength composite enclosures for battery packs and specialized thermal management materials.

One of the key players driving this innovation is LIFT, the Detroit-based national manufacturing innovation institute. Located in the Corktown neighborhood, LIFT works at the intersection of materials science and manufacturing processes. Their work ensures that as new alloys are discovered, local factories actually have the capacity and know-how to mass-produce them.

“The future of manufacturing isn’t just about the assembly line; it’s about the molecular structure of the parts we assemble,” a spokesperson for a local automotive supplier noted during a recent industry roundtable. “Detroit is uniquely positioned because we have the engineering density to solve these material challenges faster than anywhere else.”

Impact on Detroit Residents

For the local workforce, the rise of advanced materials manufacturing brings both opportunities and challenges. These are not the dirty, dangerous factory jobs of the past, but they are also not jobs that can be performed without specific training.

The shift requires a workforce skilled in operating CNC machinery, understanding composite layering, and managing automated quality control systems. This evolution is sparking a new wave of workforce development programs. Organizations across the city are partnering with institutions like Wayne State University to offer certification programs specifically designed for these high-tech manufacturing roles.

For Detroit residents, this means access to careers that offer higher stability and wages compared to traditional assembly roles, which are increasingly susceptible to automation. Local leaders emphasize that this sector is critical for sustaining middle-class growth in the city. You can read more about how these changes are influencing the local job market in our report on Detroit workforce development trends.

Background & Data

The push for advanced materials is backed by significant data regarding industry trends. A 2024 report by the Center for Automotive Research indicated that the average vehicle content of aluminum and magnesium is expected to double by 2030 to offset battery weight. furthermore, the market for silicon carbide—a material critical for EV power electronics—is exploding.

Detroit’s proximity to major supply chains allows for rapid integration of these materials. Unlike Silicon Valley, which focuses on software, Detroit retains the physical infrastructure to build hardware. This “atoms over bits” advantage is attracting startups specializing in graphene and nanomaterials to set up pilot lines within the city limits.

Local real estate is also reflecting this trend. Industrial spaces in areas like the Milwaukee Junction and along the riverfront are being retrofitted not for massive assembly lines, but for smaller, clean-room style manufacturing environments required for sensitive advanced materials.

What Happens Next

As 2026 approaches, the integration of artificial intelligence into material discovery is expected to accelerate the sector even further. Detroit’s manufacturers are beginning to use AI to predict how new alloys will behave before they are even cast, shortening development cycles from years to months.

The city’s continued investment in the Detroit innovation districts suggests that leadership is betting big on this sector. If successful, Detroit will not just be the place where cars are put together, but the place where the materials of the future are invented and forged.