By Sarah Jenkins

Published: October 24, 2023

Location: Detroit, Michigan

Detroit Auto Suppliers Face Pivotal Shift Amid Electric Vehicle Transition

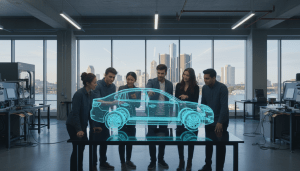

The backbone of Detroit’s economy—its vast network of automotive suppliers—is currently navigating one of the most significant transformations in industrial history. As automakers aggressively pivot toward electric vehicle (EV) production, Detroit auto suppliers are finding themselves at a crossroads that requires rapid innovation, workforce retraining, and significant capital investment.

For decades, the supply chain in Southeast Michigan has been optimized for the internal combustion engine (ICE). However, with the industry moving toward electrification, local manufacturers are restructuring operations to remain competitive in a changing global market.

The EV Transition and Supply Chain Resilience

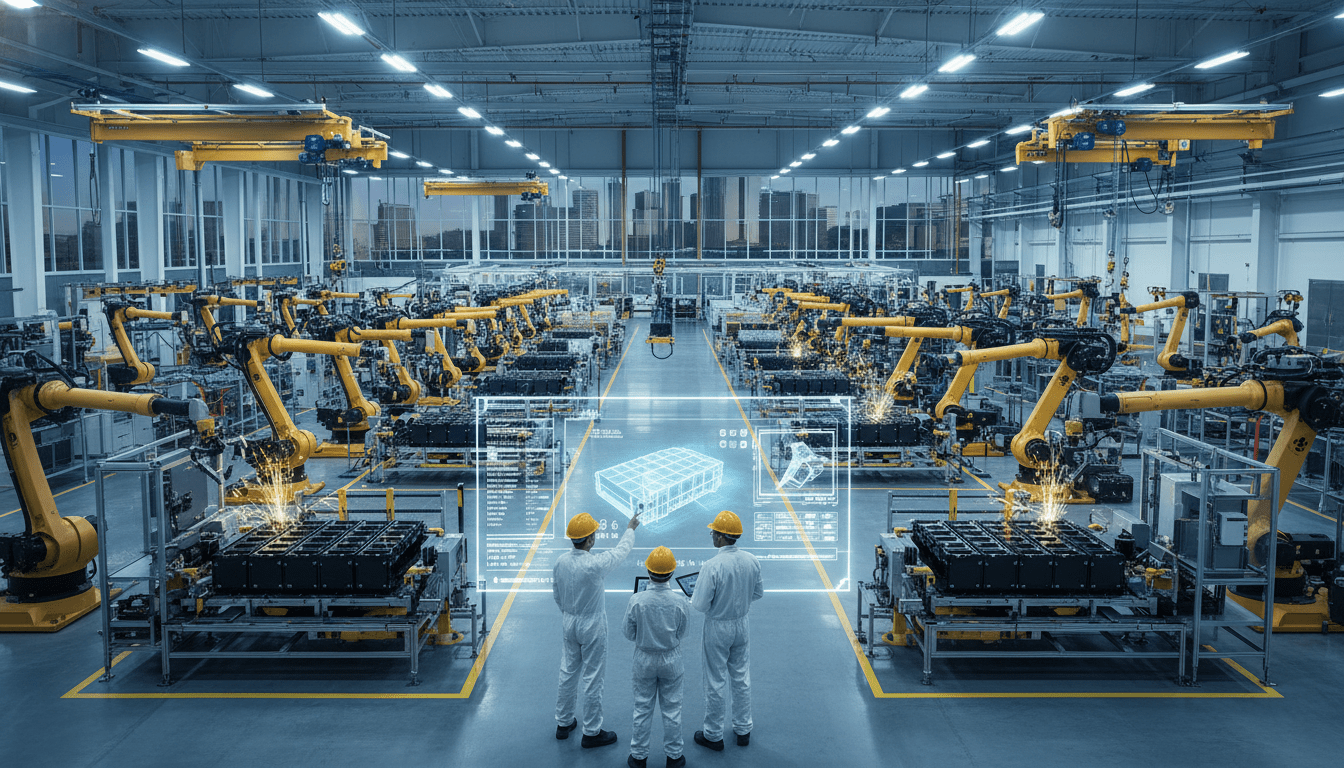

The shift to electrification is not merely a change in the product but a fundamental overhaul of the components required to build a vehicle. Traditional parts such as exhaust systems, fuel injectors, and multi-speed transmissions are being replaced by battery packs, electric motors, and advanced thermal management systems.

According to research from the Center for Automotive Research (CAR), this transition poses both a risk and an opportunity for the region. While some legacy components will see reduced demand, the need for software-defined vehicle architectures and high-voltage electronics is skyrocketing. Suppliers in the Metro Detroit area are increasingly partnering with tech firms or spinning off new divisions to capture this emerging market share.

“The supply base is under immense pressure to dual-track their operations,” said an analyst covering the Midwest automotive sector. “They must continue to produce high-quality parts for gas vehicles, which still generate the bulk of the revenue, while simultaneously investing billions into EV technologies that are not yet fully profitable.”

Impact on Detroit Residents and Workforce

This industrial pivot has direct implications for the local workforce in Detroit. As factories retool, the skill sets required on the assembly line are changing. There is a growing demand for workers proficient in electrical engineering, battery chemistry, and robotics maintenance.

For Detroit residents, this means that job security in the coming decade will largely depend on access to retraining programs. Local initiatives and partnerships between community colleges and Detroit auto suppliers are aiming to bridge the skills gap. The goal is to ensure that the workers who built the Motor City’s legacy are not left behind as the technology evolves.

Furthermore, the health of these suppliers directly impacts the broader regional economy. A robust supplier network supports thousands of indirect jobs, from logistics and warehousing to local service industries like restaurants and catering that serve industrial parks.

Background & Data: The Economic Stake

Data from MEMA, The Vehicle Suppliers Association, indicates that vehicle suppliers manufacture over 77% of the value of a new vehicle. Michigan remains the undisputed center of this activity, hosting more than 1,600 automotive-related manufacturing establishments.

However, the financial landscape is tightening. Higher interest rates and lingering supply chain disruptions from the post-pandemic era have squeezed profit margins. Smaller Tier 2 and Tier 3 suppliers are particularly vulnerable, lacking the deep pockets of Tier 1 giants to weather long transition periods.

What Happens Next?

Looking ahead to 2025, the consolidation of the supply chain seems inevitable. Industry experts predict a wave of mergers and acquisitions as larger entities absorb smaller innovators to acquire their technology or manufacturing capacity. For Detroit, the priority remains keeping these manufacturing hubs local rather than seeing production move to the southern United States or overseas.

The resilience of Detroit auto suppliers has been tested before, from the 2008 financial crisis to recent chip shortages. The current shift to electrification represents the next great challenge, determining the region’s economic trajectory for the next generation.