In the rapidly shifting landscape of the global economy, few cities have weathered as much transformation as Detroit. Yet, as 2025 unfolds, the "Motor City" is aggressively reaffirming its position as one of the world’s premier Detroit car manufacturing hubs. With the industry pivoting toward electrification and autonomous technology, Southeast Michigan is seeing a resurgence in industrial investment, challenging narratives that the region’s manufacturing prime is in the past.

While competition from southern U.S. states and international markets like China and Mexico remains fierce, Detroit’s unique combination of established infrastructure, engineering talent, and deep-seated industrial legacy provides a foundation that emerging hubs struggle to replicate. Major automakers, including General Motors and Ford, continue to pour billions into local facilities, signaling that the heart of the American automotive industry still beats in Michigan.

The Evolution of Detroit Car Manufacturing

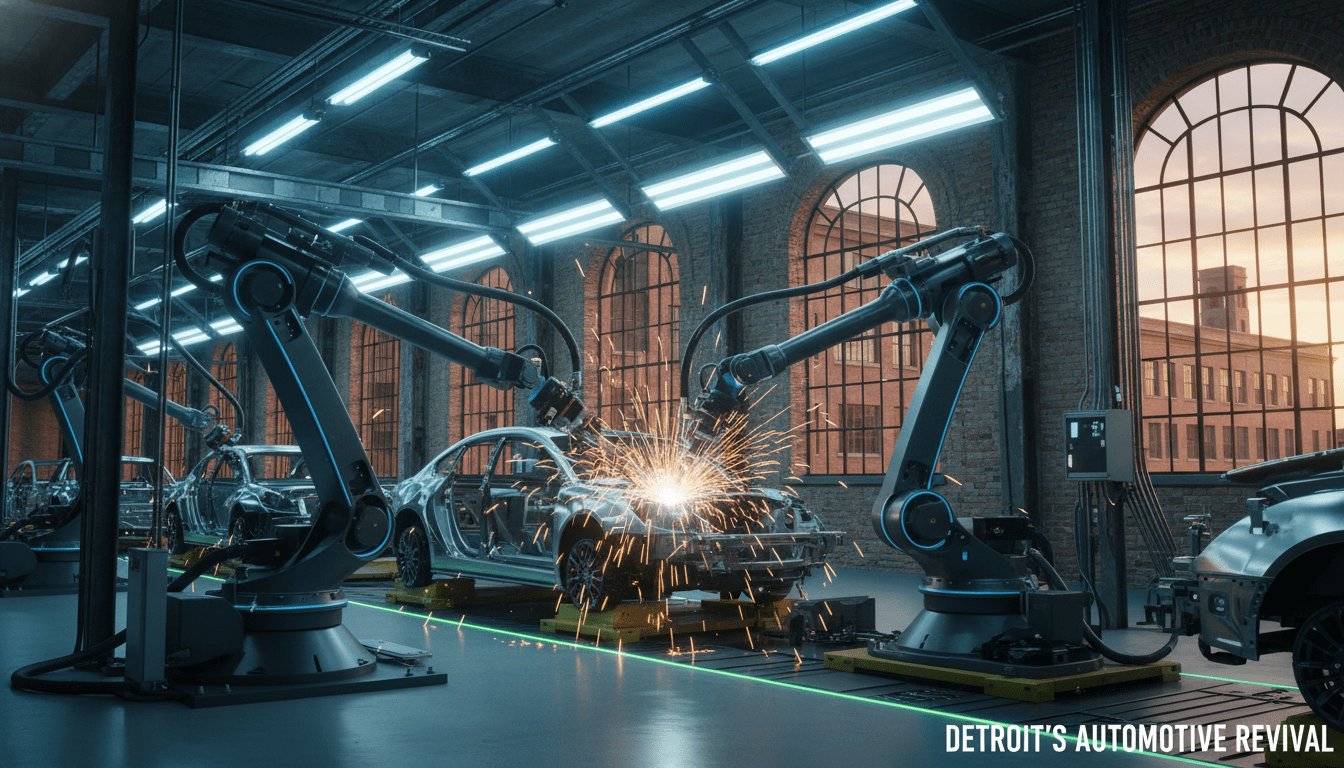

For decades, the story of Detroit car manufacturing was one of contraction. However, recent data from the Michigan Economic Development Corporation (MEDC) suggests a stabilization and pivot toward high-tech production. The traditional assembly line is disappearing, replaced by advanced robotics and software-integrated manufacturing systems designed for Electric Vehicles (EVs).

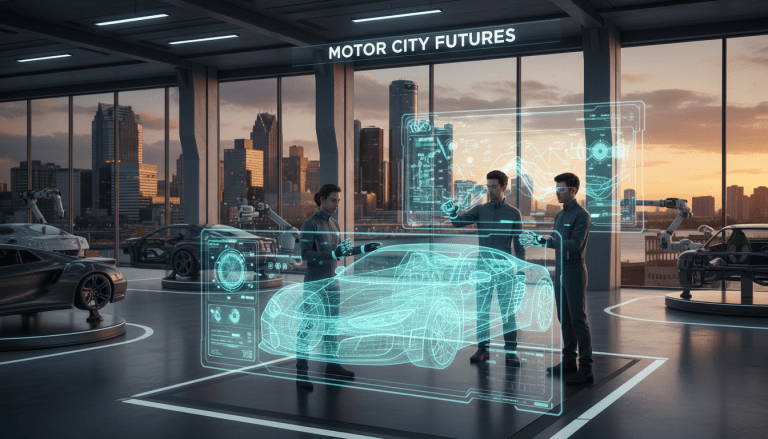

"We are seeing a fundamental shift from purely mechanical assembly to a hybrid of tech and manufacturing," said a spokesperson for the Detroit Regional Chamber in a recent press briefing. "Detroit is no longer just bending metal; we are integrating the software that defines the next generation of mobility. That is why the engineering hubs remain here, even if some assembly moves elsewhere."

This evolution is visible at sites like GM’s Factory ZERO, which straddles the Detroit-Hamtramck border. Once slated for closure, the facility was retooled with a $2.2 billion investment to become the launchpad for the company’s multi-brand EV strategy. This revitalization serves as a microcosm for the region: adapting legacy assets for a sustainable future.

Impact on Detroit Residents and the Local Economy

For local residents, the stakes of maintaining Detroit’s status among top Detroit car manufacturing hubs are high. The automotive sector remains the largest multiplier of jobs in the region. According to the U.S. Bureau of Labor Statistics, manufacturing jobs in the Detroit-Warren-Dearborn area have shown resilience, despite broader national fluctuations.

However, the nature of these jobs is changing. The demand for unskilled labor is decreasing, while the need for mechatronics technicians and software-literate operators is surging. This skills gap presents both a challenge and an opportunity for the city’s workforce development programs.

Local educational institutions and trade unions are rushing to fill this void. "The job isn’t just putting a bolt on a wheel anymore," explained a representative from UAW Local 600. "Our members are being trained on systems that didn’t exist five years ago. This transition is crucial for keeping families in the middle class."

For the average Detroiter, a healthy manufacturing sector means a stronger tax base for city services. Revenue generated from these massive industrial footprints supports everything from public parks and libraries to emergency services. When the assembly lines are running, the local restaurants, logistics companies, and service providers that support the factories thrive.

The Electric Vehicle Transition

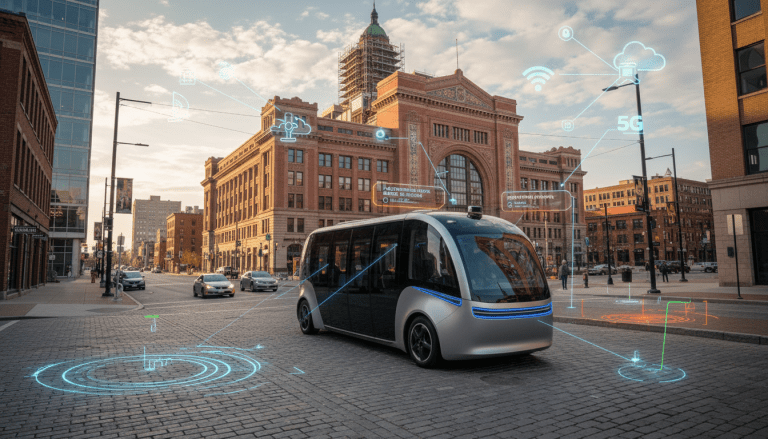

The transition to EVs is the primary driver reshaping Detroit car manufacturing today. Ford’s continued commitment to the Rouge Electric Vehicle Center in Dearborn highlights the proximity of production to engineering headquarters. Unlike internal combustion engines, which rely on complex supply chains of transmission and engine parts, EVs rely heavily on battery cells and software.

This shift has sparked a race to localize the battery supply chain. Michigan officials have been aggressive in securing battery plant investments to ensure that the value chain remains within the state. The logic is clear: if the batteries are made elsewhere, the assembly plants might eventually follow. By securing battery manufacturing near Detroit, the region locks in the assembly jobs for the foreseeable future.

Challenges from Emerging Hubs

Despite the optimism, Detroit faces significant headwinds. Southern states like Tennessee, Kentucky, and Georgia have attracted massive investments from Ford, SK On, and other entities, offering lower energy costs and different labor regulations. Furthermore, international pressure remains constant.

Critics often point to the high cost of doing business in the Midwest. However, proponents argue that the density of suppliers in Southeast Michigan creates an efficiency that is hard to replicate. A study by the Center for Automotive Research indicates that Michigan still holds the highest concentration of automotive R&D talent in North America. For automakers, the proximity between the design studio, the engineering lab, and the factory floor in Detroit is a logistical advantage that saves time and money during complex vehicle launches.

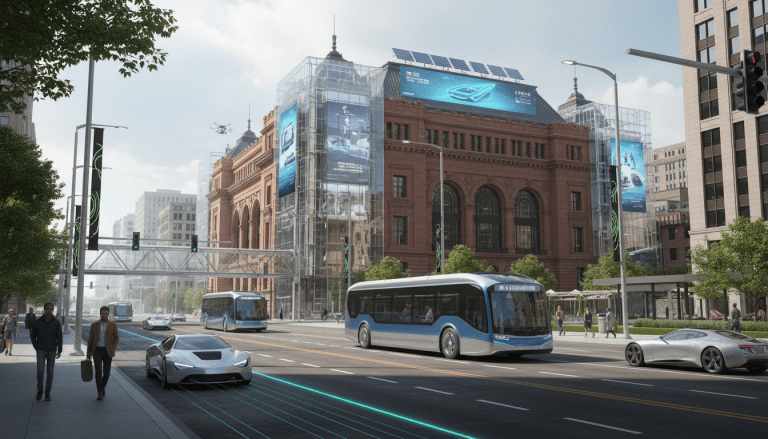

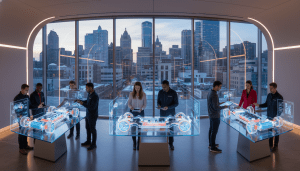

Future Outlook: A High-Tech Manufacturing Hub

Looking ahead to the remainder of the decade, Detroit car manufacturing will likely become smaller in physical footprint but higher in economic value. The days of sprawling factories employing 20,000 people at a single site are likely over. Instead, the region is moving toward flexible manufacturing campuses that can switch between vehicle models—gas, hybrid, or electric—based on real-time consumer demand.

City officials are also focused on repurposing vacant industrial land for Tier 1 and Tier 2 suppliers, creating a tighter supply loop. This aligns with broader real estate development goals aimed at revitalizing industrial corridors.

Ultimately, Detroit’s identity is evolving. It is no longer the undisputed monopolist of car production, but it remains the brain center of the industry. As vehicles become computers on wheels, Detroit is positioning itself as the Silicon Valley of mobility, ensuring that while the cars of the future may be silent, the local economy will continue to hum.