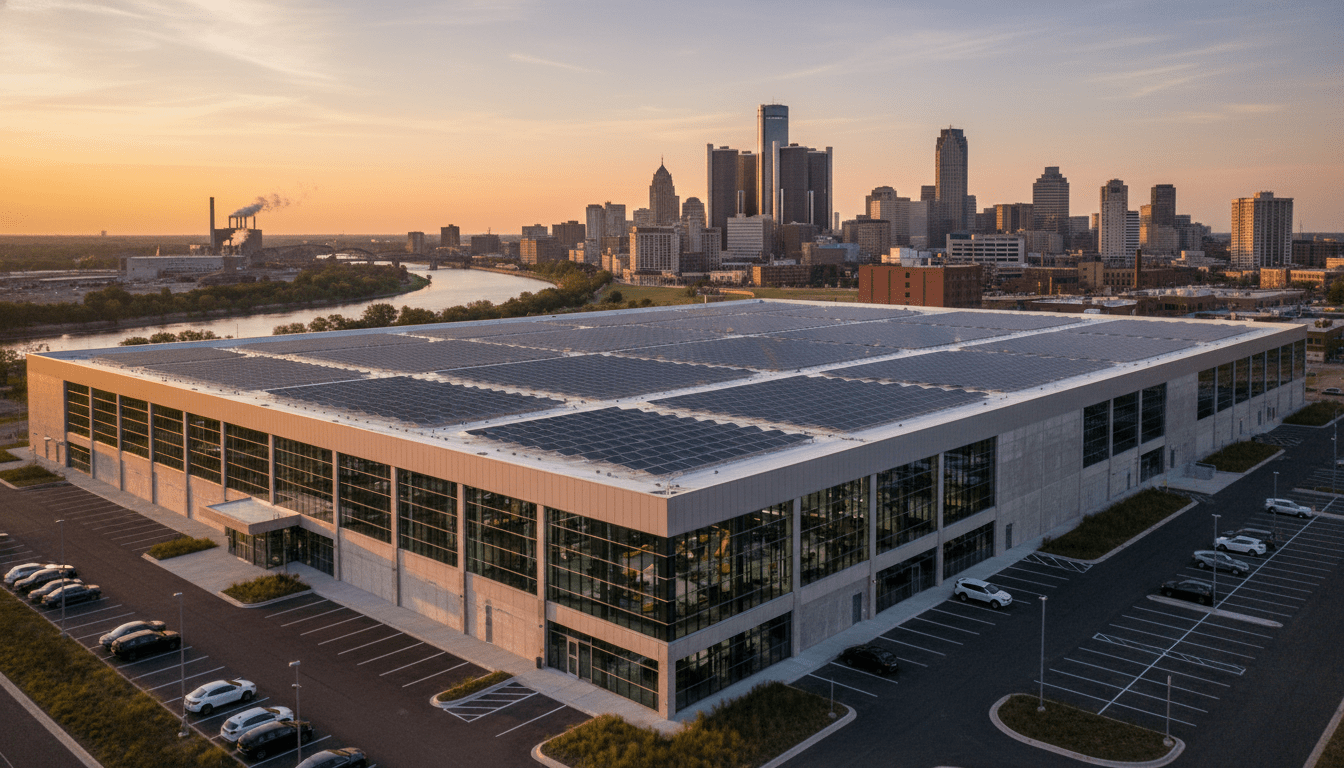

For decades, the skyline of Detroit has been defined by smokestacks and the rhythmic hum of assembly lines. But a quiet revolution is taking place on the rooftops and power grids feeding the region’s industrial heartland. As the automotive industry aggressively pivots toward electric vehicles (EVs), the factories building them are simultaneously undergoing a transformation of their own: a massive shift toward renewable energy sources.

Detroit clean energy manufacturing is no longer just a corporate buzzword; it is becoming a dominant operational standard. Major automakers, local suppliers, and utility providers are collaborating to decouple industrial production from fossil fuels, driven by federal incentives, corporate sustainability goals, and a pragmatic need for energy resilience.

The Industrial Pivot to Renewables

The push for sustainable manufacturing in Southeast Michigan is being led largely by the region’s automotive giants, who are leveraging their purchasing power to demand cleaner grids. According to DTE Energy, the state’s largest energy provider, industrial enrollment in voluntary renewable energy programs has surged in the last two years.

General Motors, headquartered in the Renaissance Center, has accelerated its commitment to source 100 percent renewable energy to power its U.S. sites by 2025—five years ahead of its original target. This shift requires a massive influx of wind and solar power into the local grid.

“The manufacturing sector is realizing that clean energy isn’t just about optics; it’s about long-term cost stability,” said an analyst from the Center for Automotive Research. “With the volatility of global fossil fuel markets, locking in wind and solar contracts offers a predictable energy cost for factories that consume gigawatts of power annually.”

Much of this transition is facilitated through DTE Energy’s MIGreenPower program. The voluntary renewable energy program allows large industrial customers to attribute a percentage of their energy use to wind and solar projects within Michigan. Ford Motor Company has also made history through this initiative, finalizing a purchase agreement that aims to power all its Michigan manufacturing with clean energy, a move heavily publicized as the largest renewable energy purchase from a utility in U.S. history.

Federal Policy Fueling Local Change

While corporate goals provide the destination, federal policy is providing the fuel. The Inflation Reduction Act (IRA) has directed billions toward clean energy manufacturing credits, making it financially viable for Detroit factories to upgrade their infrastructure.

According to data from the U.S. Department of Energy (DOE), Michigan has attracted over $20 billion in clean energy and EV manufacturing investments since the passage of recent federal climate laws. This influx is not only for building EVs but for retrofitting existing facilities to operate more efficiently.

Local suppliers are following suit. Smaller Tier 1 and Tier 2 manufacturing shops in Macomb and Oakland counties are increasingly installing onsite solar arrays and upgrading HVAC systems to reduce their carbon footprint, often required to meet the stringent supply chain sustainability mandates set by the Big Three.

Impact on Detroit Residents

For the average Detroiter, the shift toward Detroit clean energy manufacturing offers two distinct impacts: economic opportunity and environmental health.

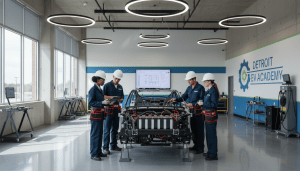

New Jobs and Skills

The transition requires a workforce skilled in new technologies. It isn’t just about assembly lines anymore; it is about energy management, solar installation, and grid maintenance. Local trade unions are adapting their apprenticeship programs to include renewable energy certifications.

We recently reported on the surge in demand for technical roles in our article on Detroit’s evolving tech workforce, noting that “green collar” jobs are becoming a significant slice of the local employment pie.

Environmental Justice

Perhaps more immediately relevant to residents in neighborhoods like Southwest Detroit—historically burdened by heavy industrial pollution—is the potential for improved air quality. As factories reduce their reliance on on-site combustion and the regional grid becomes less dependent on coal plants, local emissions of particulate matter are projected to decrease.

Local community organizers have long advocated for this shift. “For generations, our neighborhoods have powered the economy at the cost of our lungs,” said a representative from a Southwest Detroit environmental justice group. “Seeing factories switch to solar and wind is a start, but we need to ensure that the benefits of this transition reach the residents living in the shadows of these plants.”

Challenges to the Grid

Despite the optimism, the transition is not without significant hurdles. The primary challenge remains grid reliability. Manufacturing plants require consistent, high-load power. Solar and wind are intermittent by nature, requiring robust battery storage solutions and grid upgrades to ensure that assembly lines do not stop when the sun sets or the wind dies down.

DTE Energy has faced scrutiny regarding service reliability in residential areas, a topic covered extensively in our recent piece on DTE’s infrastructure struggles. Critics argue that while industrial partners are getting premium green energy access, residential infrastructure needs to keep pace to prevent disparities in service quality.

What Happens Next

Looking ahead to late 2025 and beyond, the trajectory for Detroit clean energy manufacturing is steep. The Michigan Public Service Commission continues to approve new solar parks, many of which are designated specifically to support industrial load.

Furthermore, Detroit is beginning to see the emergence of “circular manufacturing” hubs, where battery recycling and material recovery are powered entirely by renewables. This creates a closed-loop system that could define the next century of the Motor City’s industrial identity.

As the factories that put the world on wheels begin to run on the wind and sun, Detroit is once again positioning itself as a global leader—this time, in the era of sustainable production.