For over a century, the rhythm of Detroit has been set by the firing order of internal combustion engines. The pistons, crankshafts, and transmissions produced in the Motor City defined the global automotive landscape. However, a silent revolution is currently underway on the factory floors of Southeast Michigan. As the industry pivots aggressively toward electrification, the region is rapidly transforming into the global capital for electric drivetrain technology, a shift that promises to redefine the local economy, workforce, and industrial identity.

The transition is no longer theoretical. From the retooling of historic assembly plants to the construction of massive battery cell manufacturing facilities, Detroit is moving from mechanical complexity to software-defined electrical efficiency. This evolution presents both a massive opportunity and a significant challenge for the city that put the world on wheels.

Defining the New Heart of the Car

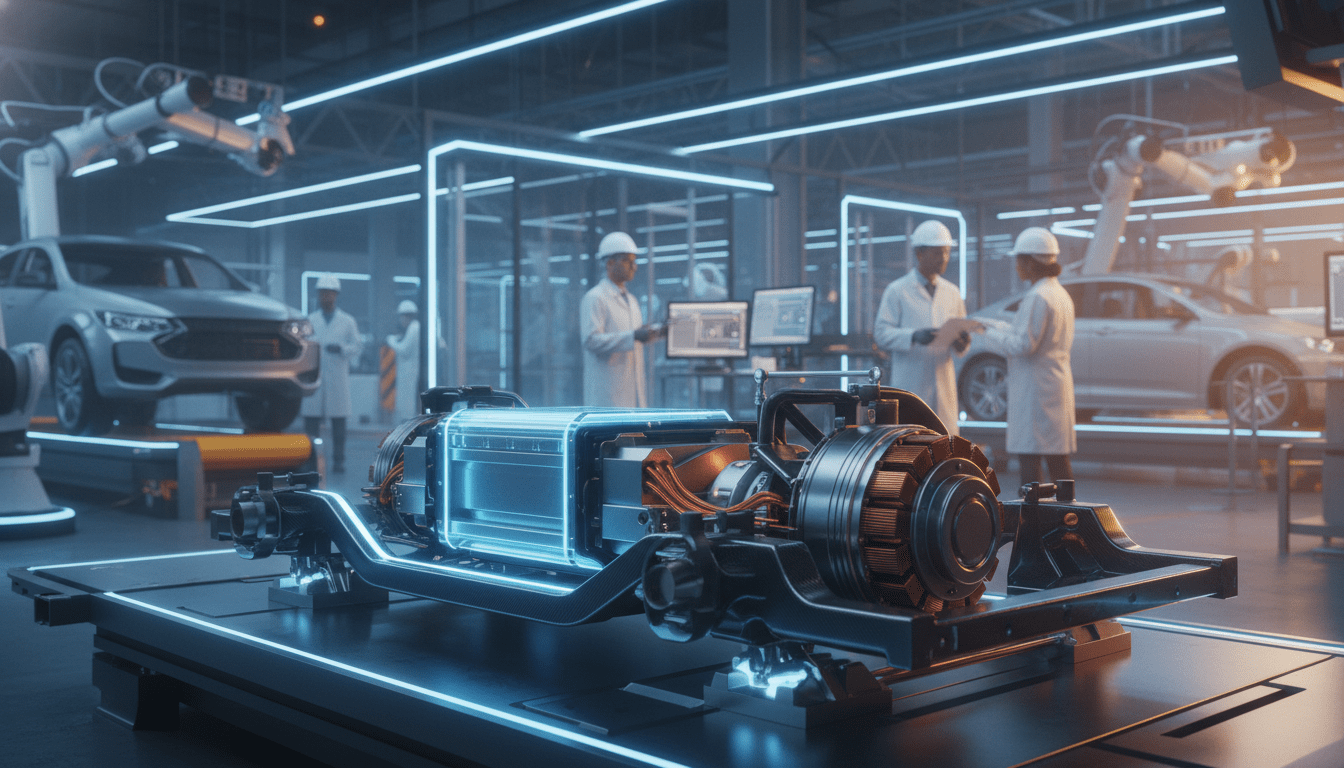

To understand the magnitude of this shift, one must understand the technology itself. Unlike traditional internal combustion engine (ICE) vehicles, which rely on thousands of moving parts, an EV’s propulsion system is centered around the electric drivetrain. This system primarily consists of the battery pack, the inverter, and the electric motor (or e-motor), often integrated into a single unit known as an e-axle.

“The engineering challenge has shifted from combustion efficiency to thermal management and power density,” explains Dr. Alan Reynolds, an automotive systems analyst who tracks supply chain shifts in the Midwest. “Detroit’s legacy suppliers are currently in a race to master the production of these high-voltage systems. It is not just about swapping an engine for a motor; it is about redesigning the entire architecture of the vehicle.”

According to reports from the Michigan Economic Development Corporation (MEDC), the state has secured more than $16 billion in electric vehicle and battery manufacturing investments since 2019. A significant portion of this capital is dedicated to developing proprietary electric drivetrain technology, ensuring that the intellectual property remains within the Detroit metro area rather than being outsourced overseas.

Impact on Detroit Residents and the Workforce

For the average Detroiter, this technological pivot has tangible implications. The nature of automotive work is changing. While traditional assembly jobs remain, there is a surging demand for technicians skilled in high-voltage electronics, mechatronics, and software integration. This demand is driving wage growth in specific sectors but also creating a skills gap that local institutions are rushing to fill.

Local educational partnerships are expanding to meet this need. Wayne State University and various community colleges in the Metro Detroit area have launched certificate programs specifically focused on EV components. For residents, this offers a pathway to future-proof careers in Detroit’s evolving job market.

“We are seeing a transition where a line worker needs to be comfortable with diagnostics tools that look more like tablets than wrenches,” said a representative from a local UAW chapter during a recent workforce development roundtable. “The electric drivetrain technology requires a cleaner, more precise manufacturing environment, which improves working conditions but raises the bar for entry-level training.”

Industry Titans and Local Innovation

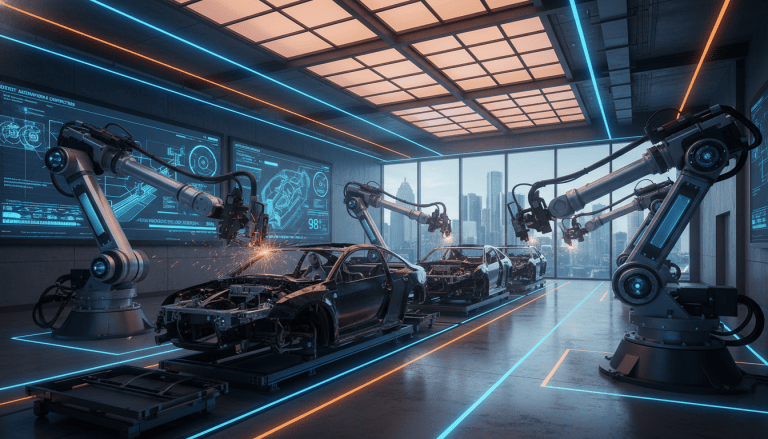

The Big Three—General Motors, Ford, and Stellantis—are heavily investing in bringing drivetrain production in-house. GM’s Factory ZERO, straddling the Detroit-Hamtramck border, stands as a testament to this commitment. The facility has been completely retooled to produce electric trucks and SUVs, utilizing the company’s Ultium battery and drive unit platform.

However, the ecosystem extends beyond the major OEMs. Tier 1 suppliers like BorgWarner and Magna, which have significant footprints in the Detroit metro area, are developing integrated drive modules that combine the motor, transmission, and inverter. These components are critical for reducing the weight and increasing the range of next-generation electric vehicles.

“Detroit has the advantage of density,” notes the Center for Automotive Research in a recent industry brief. “You have the battery chemists, the motor engineers, and the assembly plants all within a 50-mile radius. That proximity is vital for iterating on complex electric drivetrain technology quickly.”

Background and Market Data

The urgency to dominate this sector is driven by global competition and regulatory timelines. Data from the U.S. Bureau of Labor Statistics indicates that employment in battery and electrical equipment manufacturing has been one of the fastest-growing sub-sectors in Michigan over the last 24 months. Furthermore, federal incentives provided by the Inflation Reduction Act have accelerated the domestication of the EV supply chain, making it financially advantageous to manufacture these drivetrains in Detroit rather than importing them.

Despite the optimism, hurdles remain. The local business community is still navigating the supply chain volatility associated with raw materials like lithium and cobalt, which are essential for the battery component of the drivetrain.

What Happens Next?

Looking ahead to 2026 and beyond, the focus on electric drivetrain technology in Detroit is expected to intensify. The next frontier involves solid-state batteries and even more efficient silicon-carbide inverters. As these technologies mature, the cost of EVs is projected to reach parity with combustion vehicles, likely triggering a mass-market tipping point.

For Detroit, the message is clear: the city is not just assembling cars; it is engineering the future of propulsion. By anchoring the development and manufacturing of electric drivetrains locally, Detroit is securing its position as the indispensable hub of the 21st-century automotive industry.