Detroit, long heralded as the automotive capital of the world, is currently undergoing a significant industrial metamorphosis. While the assembly line defined the city’s economic past, Detroit mobility innovation is rapidly defining its future. The region is transitioning from traditional vehicle production to a high-tech ecosystem focused on electric vehicles (EVs), autonomous transportation, and smart infrastructure, a shift that promises to reshape the local economy and workforce.

This evolution is not merely about changing the types of vehicles produced; it represents a fundamental overhaul of the manufacturing sector. As global demand shifts toward sustainable and connected transportation, Detroit is positioning itself to lead the charge, leveraging its historical engineering prowess to court major investments in technology and advanced manufacturing.

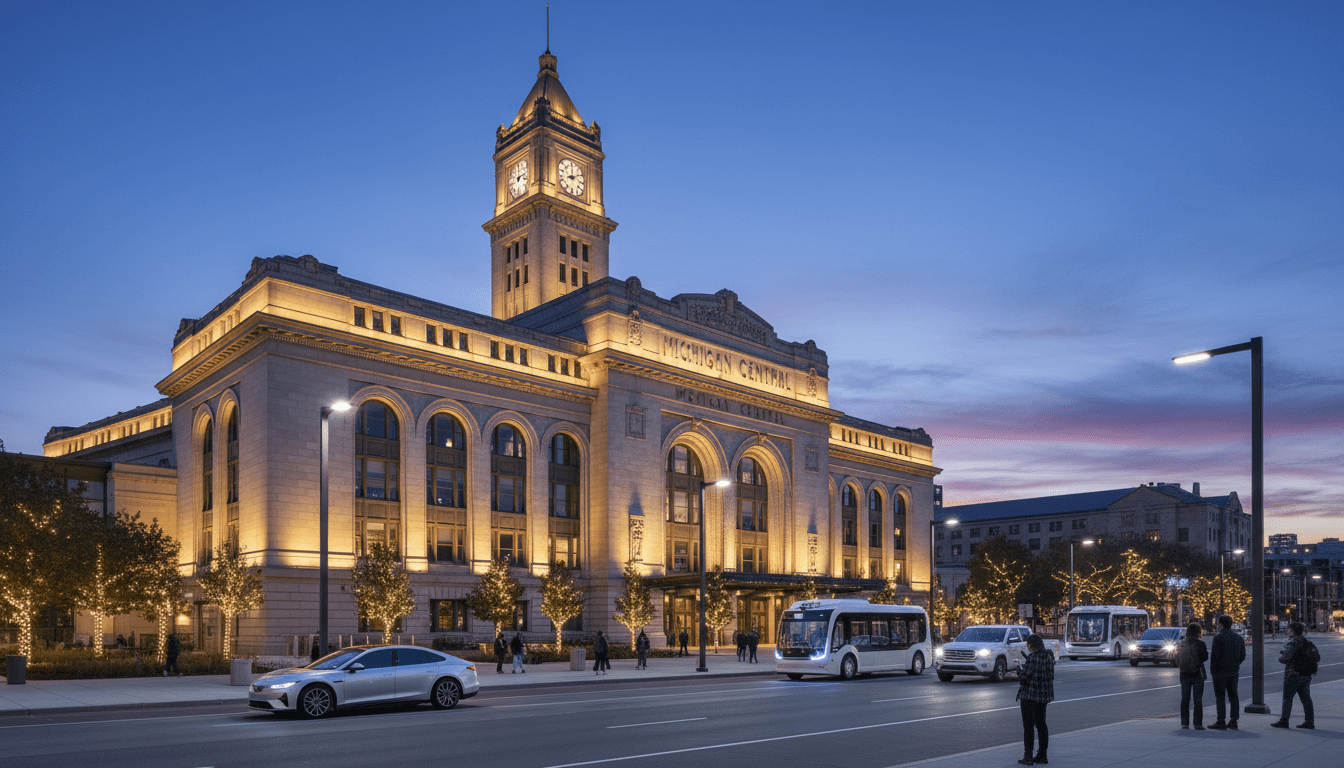

The Anchor of Innovation: Michigan Central

Central to this narrative is the reopening and repurposing of Michigan Central Station. Once a symbol of the city’s decline, the station has been transformed by Ford Motor Company into the centerpiece of a 30-acre innovation district. According to Ford, the campus is designed to serve as a testing ground for real-world mobility solutions, bringing together startups, established tech companies, and urban planners.

The district is not just an office park; it is an active laboratory. The infrastructure surrounding the station allows for the testing of wireless charging roads, autonomous delivery drones, and connected traffic signals. This concentration of resources is intended to accelerate the development of technologies that will define technological advancements in the transportation sector for decades to come.

“The convergence of automotive and technology sectors is happening right here,” said a spokesperson for the Michigan Central district during a recent press briefing. “We are creating an environment where the hardware of the car meets the software of the internet, and that requires a new kind of manufacturing ecosystem.”

The Shift to Electric Manufacturing

Beyond the software and R&D hubs, the physical manufacturing landscape in Detroit is pivoting heavily toward electrification. General Motors and Stellantis have both committed billions of dollars to retool existing plants within Michigan for EV production. This transition involves more than just swapping out engines for batteries; it requires an entirely new supply chain.

Battery cell manufacturing has become a priority for the state. New facilities are being developed to ensure that the components powering the next generation of vehicles are built locally. This vertical integration is crucial for the region to maintain its competitive edge against global markets, particularly in Asia and Europe.

Impact on Detroit Residents

For the residents of Detroit, this high-tech shift brings both opportunities and challenges. The nature of factory work is changing. The repetitive assembly jobs of the 20th century are being supplemented—and in some cases replaced—by roles that require skills in robotics management, software troubleshooting, and electrical engineering.

This transition necessitates a robust focus on workforce development. Local organizations and the City of Detroit are working to bridge the skills gap. Initiatives like local workforce development programs through “Detroit at Work” are offering training for these specific “new-collar” jobs.

However, concerns regarding equitable access remain. Community leaders have emphasized that the economic benefits of Detroit mobility innovation must reach the neighborhoods, not just the commercial districts. Ensuring that long-time Detroiters are the first in line for these new high-tech manufacturing roles is a stated priority for the Mayor’s office, which has tied tax incentives for developments to hiring mandates for local residents.

Background & Data

The scale of investment in Michigan’s mobility sector provides context for this transformation. According to the Michigan Economic Development Corporation (MEDC), the state has secured over $16 billion in electric vehicle and battery manufacturing investments since 2019. This influx of capital is projected to create or retain tens of thousands of jobs over the next decade.

Data from the Detroit Regional Chamber indicates that the mobility sector is growing faster than the general manufacturing sector. The concentration of engineering talent in Metro Detroit remains the highest in the United States, providing a fertile ground for these investments to take root.

What Happens Next

Looking ahead, the integration of manufacturing and mobility technology will likely deepen. The next phase involves the widespread deployment of “smart city” infrastructure that communicates directly with vehicles. The Michigan Department of Transportation (MDOT) is currently experimenting with connected corridors, including parts of I-94, to facilitate vehicle-to-infrastructure (V2I) communication.

As Detroit continues to refine these technologies, the city aims to export not just cars, but the blueprints for modern transportation systems. The success of this pivot will depend on the continued collaboration between the public sector, the “Big Three” automakers, and the burgeoning startup community rooted in Corktown and Midtown.