For decades, the rhythm of Detroit was set by the mechanical thrum of the assembly line—a standardized process that defined the 20th century. Today, that rhythm is changing. The Motor City is currently undergoing its most significant transformation since the days of Henry Ford, pivoting aggressively toward next-gen auto manufacturing. This shift is not merely about swapping internal combustion engines for batteries; it represents a fundamental overhaul of how vehicles are conceived, built, and maintained, driven by artificial intelligence, robotics, and the Industrial Internet of Things (IIoT).

As automakers race to meet federal electrification targets and consumer demand for smarter vehicles, Detroit’s factories are becoming high-tech laboratories. This evolution promises to revitalize the local economy, but it also presents a complex challenge for the region’s workforce, requiring a rapid shift in skills and infrastructure.

The Era of Industry 4.0 in Detroit

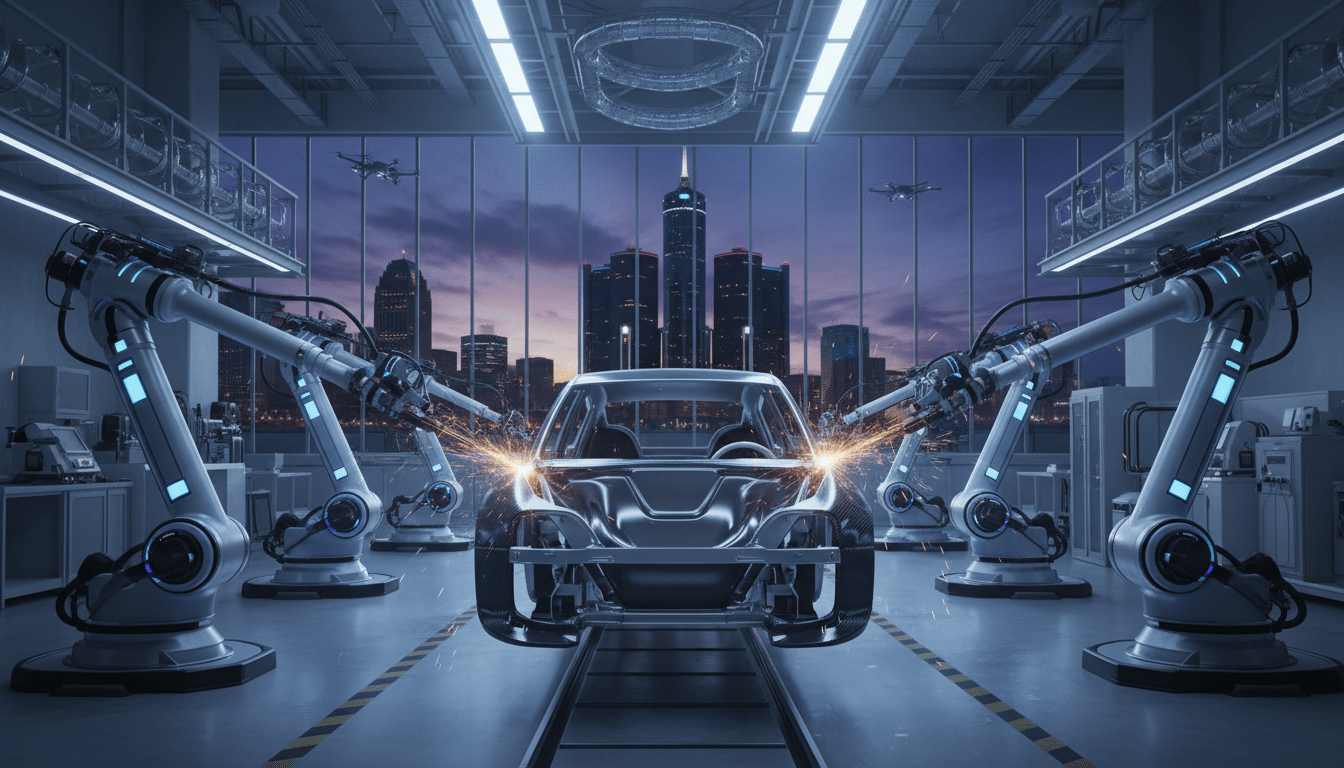

The term “Industry 4.0” is frequently tossed around in tech circles, but in Detroit, it is becoming a physical reality. Next-gen auto manufacturing relies heavily on connectivity and data. According to reports from the Michigan Economic Development Corporation (MEDC), the integration of automation in Michigan assembly plants has accelerated significantly over the last three years. The modern factory floor is no longer just about heavy stamping presses; it is about “cobots” (collaborative robots) working alongside humans and “digital twins”—virtual replicas of physical systems that allow engineers to test changes before implementing them.

General Motors’ Factory ZERO, straddling the border of Detroit and Hamtramck, serves as a prime example of this transition. Retooled specifically for electric vehicle production, the facility utilizes advanced wireless connectivity to monitor thousands of tooling systems in real-time. This allows for predictive maintenance, ensuring that machines are fixed before they break, drastically reducing downtime.

However, the shift extends beyond the Big Three. Tier 1 and Tier 2 suppliers throughout the metro area are upgrading their capabilities. Local machining shops that once produced distinct engine components are now investing in 3D printing and additive manufacturing technologies to create lighter, more complex parts required for electric vehicle architectures.

Impact on Detroit Residents and the Workforce

For the residents of Detroit, the rise of next-gen auto manufacturing is a double-edged sword. On one hand, it secures the city’s status as a global hub for innovation, preventing the industrial decline that plagued the region in the late 2000s. On the other hand, the nature of the work is changing rapidly, creating a skills gap that local officials are scrambling to close.

Traditional line jobs, which relied heavily on manual repetition, are gradually being replaced or augmented by roles that require digital literacy. Workers today are just as likely to be reading data from a tablet as they are to be wielding a torque wrench. This shift necessitates a new approach to vocational training.

Local educational institutions are responding to this need. Programs at Wayne County Community College District and various trade organizations are increasingly focusing on mechatronics—a multidisciplinary field that combines robotics, electronics, and computer engineering. For Detroiters, this means that the path to a stable, middle-class income in the auto sector now requires continuous learning and certification.

Community advocates have noted that while high-tech jobs offer better safety conditions and often higher wages, accessibility remains a concern. Ensuring that residents from underinvested neighborhoods have access to these training pipelines is critical to preventing a new form of economic segregation in the city.

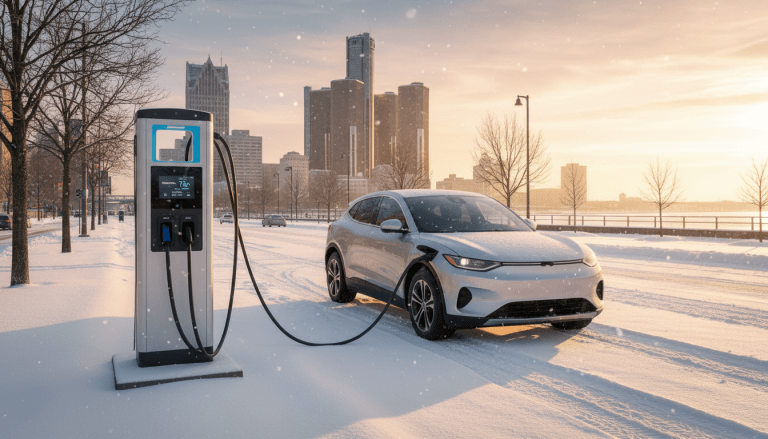

The Role of Electric Vehicles (EVs)

At the heart of next-gen auto manufacturing is the electric vehicle. The structural simplicity of an EV—containing far fewer moving parts than a gas-powered car—changes the manufacturing footprint. Engine and transmission plants, long the stalwarts of Michigan’s industrial base, are being repurposed for battery assembly and electric drive unit production.

This transition is reshaping the local real estate and development landscape. Check our recent coverage on Detroit development projects to see how industrial parks are being modernized to accommodate battery manufacturing, which requires clean-room environments and massive energy loads.

Data from the U.S. Department of Energy indicates that Michigan continues to attract a high volume of battery supply chain investments. This vertical integration—bringing battery production closer to vehicle assembly—is a strategic move to reduce logistics costs and shield production from global supply chain disruptions. For Detroit, this means the supply chain is becoming tighter and more localized, potentially boosting the local job market for logistics and specialized warehousing.

Challenges on the Horizon

Despite the optimism, the transition to next-gen auto manufacturing faces hurdles. Energy consumption is a primary concern. The high-tech factories of the future are energy-intensive, and local utility providers are working to upgrade grid infrastructure to support these demands while also trying to integrate renewable energy sources.

Furthermore, the cost of retooling is immense. While major corporations have the capital to invest in AI and robotics, smaller, family-owned suppliers in the Detroit area face significant financial pressure to modernize or risk being left behind. Industry analysts suggest that we may see a wave of consolidation among smaller suppliers in the coming years as the capital requirements for entry continue to rise.

What Happens Next?

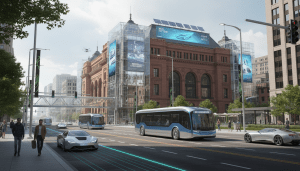

Looking toward 2030, the vision for Detroit is clear: to remain the automotive capital of the world, not by clinging to the past, but by defining the future. The convergence of Silicon Valley technology with Detroit manufacturing muscle is creating a new industrial identity for the city.

The factories being built and retooled today will produce the autonomous shuttles, electric trucks, and software-defined vehicles of tomorrow. For Detroit City News readers, the takeaway is that the industry is healthy, but it is moving fast. The definition of what it means to be an “auto worker” is evolving, and Detroit is evolving right along with it.