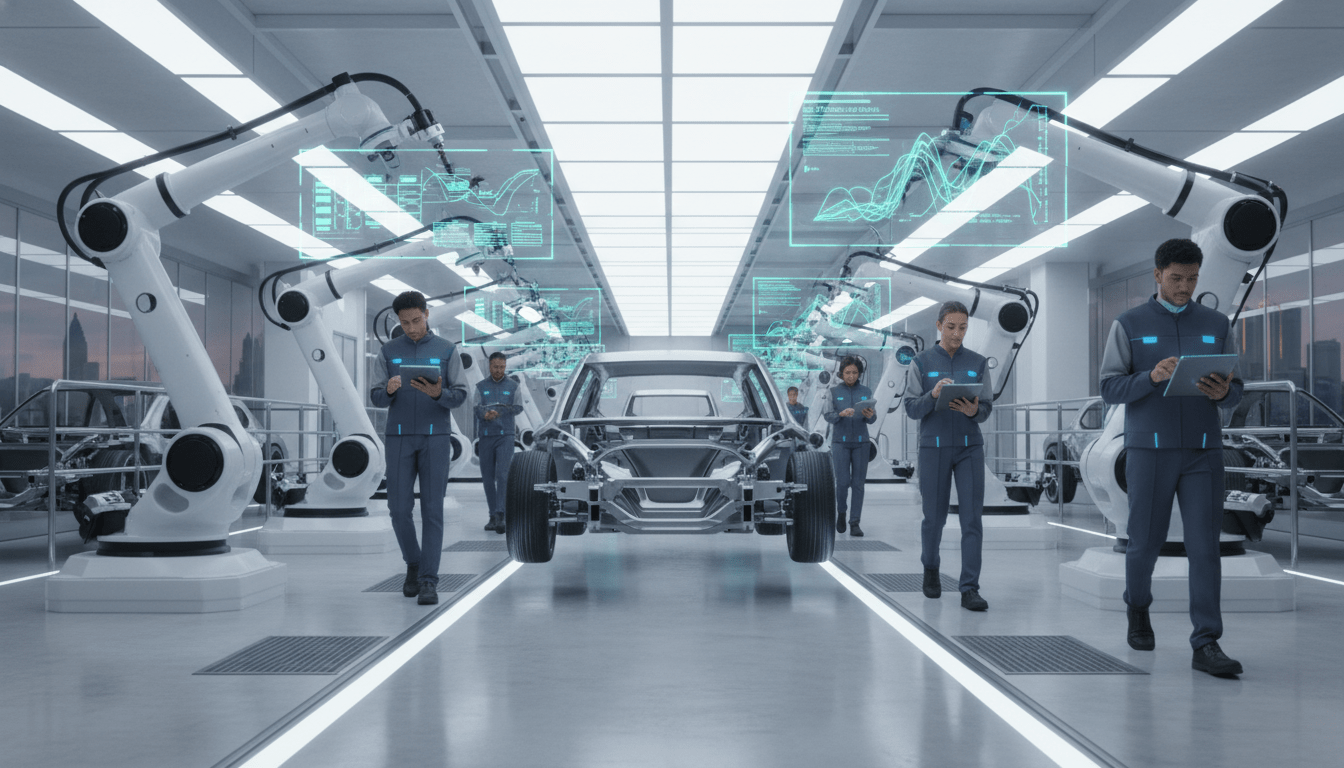

For decades, the image of Detroit manufacturing was defined by the assembly line—a mechanical marvel of efficiency introduced by Henry Ford that revolutionized the world. Today, a new revolution is quietly overhauling the region’s industrial landscape. It is no longer just about moving parts down a line; it is about data, connectivity, and artificial intelligence. Detroit smart manufacturing has arrived, and it is fundamentally altering the economic and social fabric of Southeast Michigan.

As the global automotive industry pivots toward electrification, the factories producing these vehicles are undergoing a transformation just as radical as the cars themselves. These facilities, often referred to as “smart factories” or Industry 4.0 hubs, are leveraging the Internet of Things (IoT), cloud computing, and advanced robotics to create production environments that can self-optimize in real-time.

According to data from the Automation Alley, a regional technology business association, Michigan is currently leading the nation in the adoption of Industry 4.0 technologies. This shift is not merely a technical upgrade; it represents a critical survival strategy for the region’s supply chain and a massive shift in the skills required from the local workforce.

The Rise of Industry 4.0 in Detroit

The concept of the smart factory goes beyond simple automation. While robots have been a staple of Detroit auto plants since the 1980s, the current wave of Detroit smart manufacturing involves machines that “talk” to one another. Sensors embedded in equipment monitor wear and tear to predict breakdowns before they happen, while AI algorithms adjust energy consumption to reduce waste.

Major players are leading the charge. General Motors’ Factory ZERO, straddling the border of Detroit and Hamtramck, serves as a flagship for this transition. As the launchpad for GM’s electric vehicle strategy, the facility utilizes a 5G-enabled ecosystem where tools and assembly systems are interconnected. This allows for rapid retooling and flexibility—a necessity in the volatile EV market.

“The digitization of the manufacturing floor is the single biggest opportunity for Detroit to retain its title as the manufacturing capital of the world,” says a recent report from the Workforce Intelligence Network for Southeast Michigan. The integration of digital twins—virtual replicas of physical systems—allows engineers to test changes in a virtual environment before implementing them on the physical floor, saving millions in potential downtime.

Impact on Detroit Residents and the Workforce

For the residents of Detroit, the shift toward smart factories presents a complex mix of opportunity and challenge. The narrative that robots are coming to take jobs is a persistent fear, but the reality on the ground is more nuanced. Industry experts argue that while manual, repetitive tasks are disappearing, they are being replaced by roles that require higher cognitive and technical skills.

Local educational institutions are rushing to bridge the gap. Job training programs in Detroit are increasingly focusing on mechatronics, data literacy, and robotics maintenance. Macomb Community College and Wayne State University have both expanded curricula specifically designed to feed the talent pipeline for smart manufacturing.

However, access remains a hurdle. Critics point out that without equitable access to high-speed internet and STEM education in Detroit’s neighborhoods, the benefits of this high-tech boom could bypass long-time residents. City officials have emphasized that workforce development funds must be targeted toward upskilling incumbent workers who risk displacement.

The Supply Chain Ripple Effect

While the headlines often focus on the “Big Three” automakers, the backbone of the Detroit smart manufacturing ecosystem is the thousands of small and mid-sized suppliers. These companies, which produce everything from seats to sensors, are under immense pressure to digitize.

The Michigan Economic Development Corporation (MEDC) has launched several initiatives to assist these smaller firms. Through grants and technical assistance, the state aims to ensure that a Tier 2 supplier in a Detroit industrial park can communicate digitally with a Tier 1 assembly plant. If the supply chain cannot keep up with the data requirements of the OEMs (Original Equipment Manufacturers), they risk being cut out of the loop entirely.

Local business owners have noted that the barrier to entry for smart technology is lowering. “Ten years ago, you needed a multimillion-dollar budget to have a fully connected factory,” said a production manager at a mid-sized stamping plant in Detroit. “Now, with cloud-based solutions and affordable sensors, even smaller shops can start gathering data to improve efficiency.”

Background & Data: The Economic Stakes

The economic implications of this transition are staggering. The manufacturing sector accounts for approximately 20% of Michigan’s Gross State Product. As detailed in recent analyses by the Detroit Regional Chamber, the region’s ability to dominate the Detroit smart manufacturing sector will determine its economic health for the next 50 years.

- Investment Volume: Billions are being poured into retooling existing facilities for EVs and smart tech.

- Efficiency Gains: Smart factories can increase production output by 20% while reducing energy costs by nearly 15%.

- Job Quality: Tech-enabled manufacturing roles typically pay 30% more than traditional assembly jobs, though they require specific certifications.

Furthermore, Detroit is positioning itself as a testbed for 5G connectivity, which is the nervous system of the smart factory. The density of industrial zones in the city makes it an ideal environment for deploying private 5G networks that offer the low latency required for precision robotics.

What Happens Next?

Looking ahead to 2025 and beyond, the integration of Artificial Intelligence will deepen. We are moving from “predictive maintenance” (knowing when a machine will break) to “prescriptive operations” (the machine suggesting how to run more efficiently). For Detroit’s auto industry, this is the new standard.

The City of Detroit continues to work with private partners to attract tech-focused manufacturing. The goal is to create a density of expertise that rivals Silicon Valley, but applied to the physical world of making things. As factories become smarter, the definition of a “factory worker” in Detroit is being rewritten—from a pair of hands to a manager of complex systems.

Ultimately, the success of Detroit smart manufacturing will be measured not just by the efficiency of the plants, but by how well the city integrates its workforce into this new digital era. If successful, Detroit will prove once again that it is the most innovative industrial city in America.