The hum of the assembly line—the heartbeat of Detroit for over a century—is changing. It is no longer just the sound of hydraulics and steel; it is the silent, rapid stream of data moving through fiber optic cables. Detroit is currently undergoing its most significant transformation since the moving assembly line was introduced, pivoting aggressively toward Industry 4.0.

This shift toward “smart manufacturing” is redefining the region’s economic landscape, altering the nature of the local workforce, and cementing Michigan’s status as a global leader in advanced automotive technology. As automakers and suppliers integrate Artificial Intelligence (AI), the Internet of Things (IoT), and cloud computing into their operations, the stakes for the city’s economy have never been higher.

The Rise of Detroit Smart Manufacturing

Industry 4.0 refers to the fourth industrial revolution, characterized by the marriage of physical production and digital technology. In Detroit, this means factories are becoming smarter, more autonomous, and capable of predictive maintenance that was impossible a decade ago. Major players like General Motors and Ford are retrofitting historic plants to accommodate electric vehicle (EV) production, utilizing digital twins to simulate production cycles before a single physical bolt is turned.

According to data from the Michigan Economic Development Corporation (MEDC), the state is home to a high concentration of engineering talent specifically focused on this intersection of manufacturing and technology. The push is not merely about efficiency; it is about survival in a global market where precision and speed are paramount.

“The concept of the ‘dark factory’—where robots work in the dark without human intervention—is not the reality in Detroit,” said representatives from Automation Alley, a regional manufacturing hub, in recent industry reports. “Instead, we are seeing ‘cobots’ or collaborative robots, where machines handle the dangerous or repetitive tasks, and human workers manage the data and decision-making processes.”

Impact on the Local Workforce

For Detroit residents, the transition to Industry 4.0 brings both promise and anxiety. The narrative that robots will replace human workers is a common concern, but workforce development experts in the city argue the reality is more nuanced. The demand for unskilled labor is indeed shrinking, but the demand for upskilled labor is exploding.

Local educational institutions, including Wayne State University and various community colleges, have revamped their curriculums to focus on mechatronics and digital literacy. The goal is to ensure that the resident workforce can transition from traditional assembly roles to positions managing automated systems.

“We are seeing a shift where the factory worker of tomorrow looks more like an IT professional than a traditional laborer,” noted analysts from the Center for Automotive Research (CAR). This shift requires significant investment in retraining programs. Several Detroit job programs have recently launched initiatives aimed specifically at bridging the digital divide for manufacturing workers, ensuring that long-time employees are not left behind as their factories upgrade.

Integration of AI and 5G

A critical component of Detroit smart manufacturing is connectivity. The deployment of 5G networks across industrial zones in Detroit is enabling machines to communicate with each other in real-time with near-zero latency. This connectivity allows for instant adjustments on the assembly line, reducing waste and increasing product quality.

For example, in modern EV battery plants springing up around the Metro Detroit area, sensors monitor the temperature and chemical composition of battery cells during production. If a deviation is detected, AI algorithms can adjust the machinery instantly to correct the error, saving thousands of dollars in scrapped materials. This level of precision is vital for the profitability of electric vehicles, which currently operate on thinner margins than internal combustion engine vehicles.

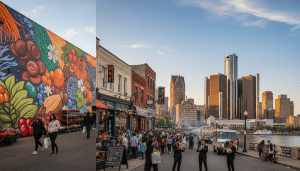

Economic Implications for the City

The economic ripple effects of Industry 4.0 extend beyond the factory walls. As manufacturing becomes more high-tech, it attracts a secondary ecosystem of software startups, cybersecurity firms, and data analytics companies to the city. This diversification is crucial for Detroit’s long-term economic stability.

Local business owners in the supply chain are also feeling the pressure to modernize. Tier 2 and Tier 3 suppliers, often smaller family-owned machine shops in the greater Detroit area, are being encouraged to adopt digital tools to integrate seamlessly with the major OEMs (Original Equipment Manufacturers). Programs like Michigan’s Industry 4.0 signature initiative act as a lifeline, providing grants and consulting to help these smaller businesses upgrade their tech stacks.

However, challenges remain. The cost of implementation for small businesses is high, and cybersecurity threats are a growing concern. As factories come online, they become targets for digital espionage and ransomware attacks, necessitating a robust cybersecurity infrastructure within the region.

What Happens Next?

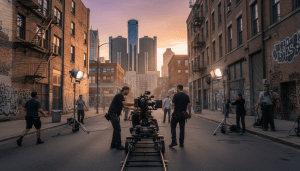

Looking ahead, the trajectory for Detroit is clear. The city is leveraging its manufacturing heritage to become a hub for the Industrial Metaverse. The redevelopment of the Michigan Central Station by Ford is a prime example of this ambition—a district dedicated to mobility innovation where the physical and digital worlds converge.

For the average Detroiter, the success of Industry 4.0 is measured not in terabytes of data, but in sustainable wages and job security. If the region can successfully upscale its workforce, Detroit stands to reclaim its title not just as the Motor City, but as the Smart Manufacturing Capital of the World.

As the industry continues to evolve, stay tuned to Detroit Auto & Business news for updates on new plant openings and workforce training opportunities available to residents.