By Sarah Jenkins

Published: October 24, 2023

Location: Detroit, Michigan

Detroit Supply Chain Modernization: Automakers Pivot to High-Tech Logistics

The industrial heartbeat of the Motor City is changing its rhythm. Following years of pandemic-induced disruptions and semiconductor shortages, the Detroit supply chain is undergoing a radical modernization effort. Major automakers and local suppliers are moving away from the fragile “just-in-time” inventory models of the past toward a robust, data-driven approach designed to withstand global shocks.

This shift is not merely administrative; it represents a fundamental overhaul of how goods move through Southeast Michigan. As the region accelerates its transition to electric vehicle (EV) manufacturing, the demand for transparency and resilience in logistics has never been higher.

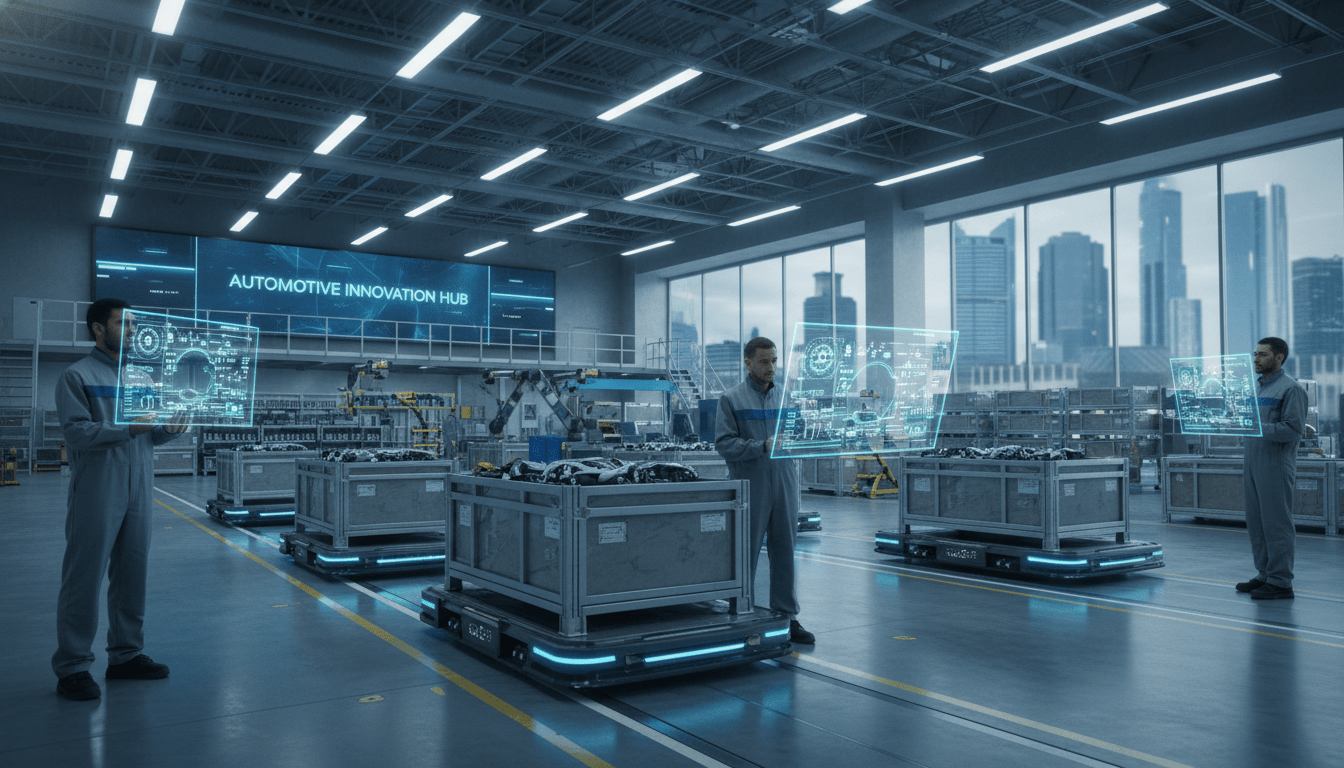

The Shift to Digital Logistics

For decades, Detroit’s automotive ecosystem relied on lean manufacturing principles. However, recent data highlights the vulnerability of those systems. According to reports from the Detroit Regional Chamber, supply chain volatility cost the North American auto industry billions in lost production between 2020 and 2022. In response, manufacturers are heavily investing in Industry 4.0 technologies—specifically Artificial Intelligence (AI) and blockchain tracking.

Local industry analysts note that the goal is “end-to-end visibility.” Automakers like General Motors and Ford are increasingly utilizing predictive analytics to foresee bottlenecks before they halt assembly lines. By digitizing the Detroit development landscape, these companies can reroute shipments or switch suppliers in real-time.

“The era of guessing where parts are is over,” said a logistics manager at a Tier 1 supplier in Sterling Heights, speaking on condition of background. “We are now integrating software that tracks components from the raw material mine all the way to the assembly plant floor. It is about securing the Detroit supply chain against future geopolitical or climate-related disruptions.”

Impact on Detroit Residents and Workforce

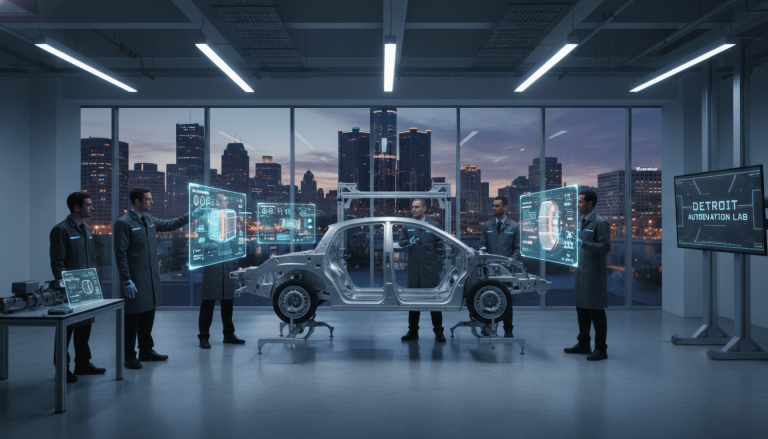

For the local workforce, supply chain modernization means a shift in required skills. The modernization of logistics is creating a demand for workers who are comfortable with data management and digital interfaces. This is no longer just about driving forklifts; it is about managing the complex digital networks that keep the forklifts moving.

According to the Michigan Economic Development Corporation (MEDC), there is a growing push to upskill the current manufacturing workforce. Programs are being rolled out to train employees in inventory management software and automated systems. This evolution aims to protect jobs by ensuring that Detroit remains the most efficient place in the world to build cars.

Furthermore, this stability is crucial for the broader Detroit economy. When assembly lines stop due to parts shortages, temporary layoffs often follow, rippling out to affect local restaurants, retail, and service providers.

Background: The EV Complication

The transition to electric vehicles adds a layer of complexity to the Detroit supply chain. EVs require entirely different components than internal combustion engines—specifically heavy batteries and rare earth minerals. Sourcing these materials requires a supply chain that is not only efficient but often geopolitical in nature.

Data from the U.S. International Trade Administration suggests that as battery manufacturing comes onshore to facilities in Michigan, the local logistics infrastructure must upgrade to handle hazardous materials and heavy loads safely and efficiently.

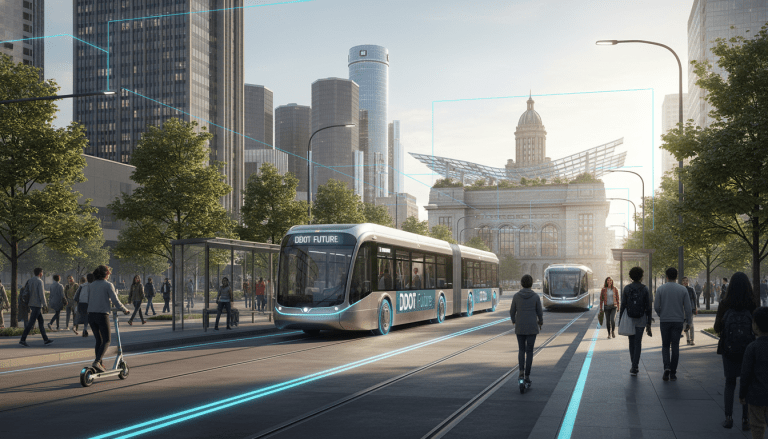

Infrastructure Upgrades

To support this, the State of Michigan is investing in infrastructure improvements around key industrial corridors. Smart corridors—roads equipped with sensors to communicate with freight trucks—are being piloted to streamline the movement of goods between suppliers and assembly plants.

What Happens Next

As 2025 approaches, the focus will likely remain on “resilience.” Experts predict a continued hybrid approach where automakers stockpile critical components while using AI to keep non-critical parts flowing lean. For Detroit, successful supply chain modernization is the key to maintaining its title as the automotive capital of the world in an increasingly digital century.