By Sarah Jenkins

Published: October 24, 2025

Location: Detroit, Michigan

Electric Truck Manufacturing: How Detroit Is Leading the EV Revolution

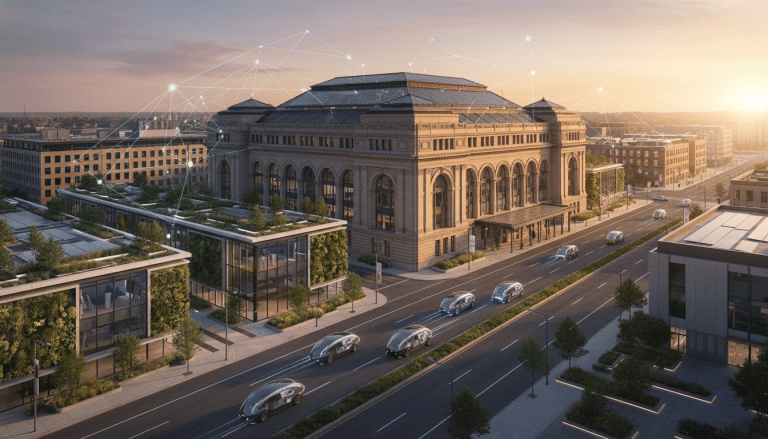

Detroit, long known as the Motor City, is undergoing one of its most significant transformations in decades. As the global automotive industry pivots toward sustainability, electric truck manufacturing has become the centerpiece of the region’s industrial strategy. Major automakers, including General Motors and Ford, are investing billions into local facilities, fundamentally changing the landscape of Detroit’s economy and workforce.

The shift is centered around flagship facilities like GM’s Factory ZERO Detroit-Hamtramck Assembly Center and Ford’s Rouge Electric Vehicle Center in nearby Dearborn. These hubs are not just producing vehicles; they are testing the viability of a large-scale transition from internal combustion engines to battery-electric powertrains in the heavy-duty sector.

The State of Electric Truck Manufacturing in Detroit

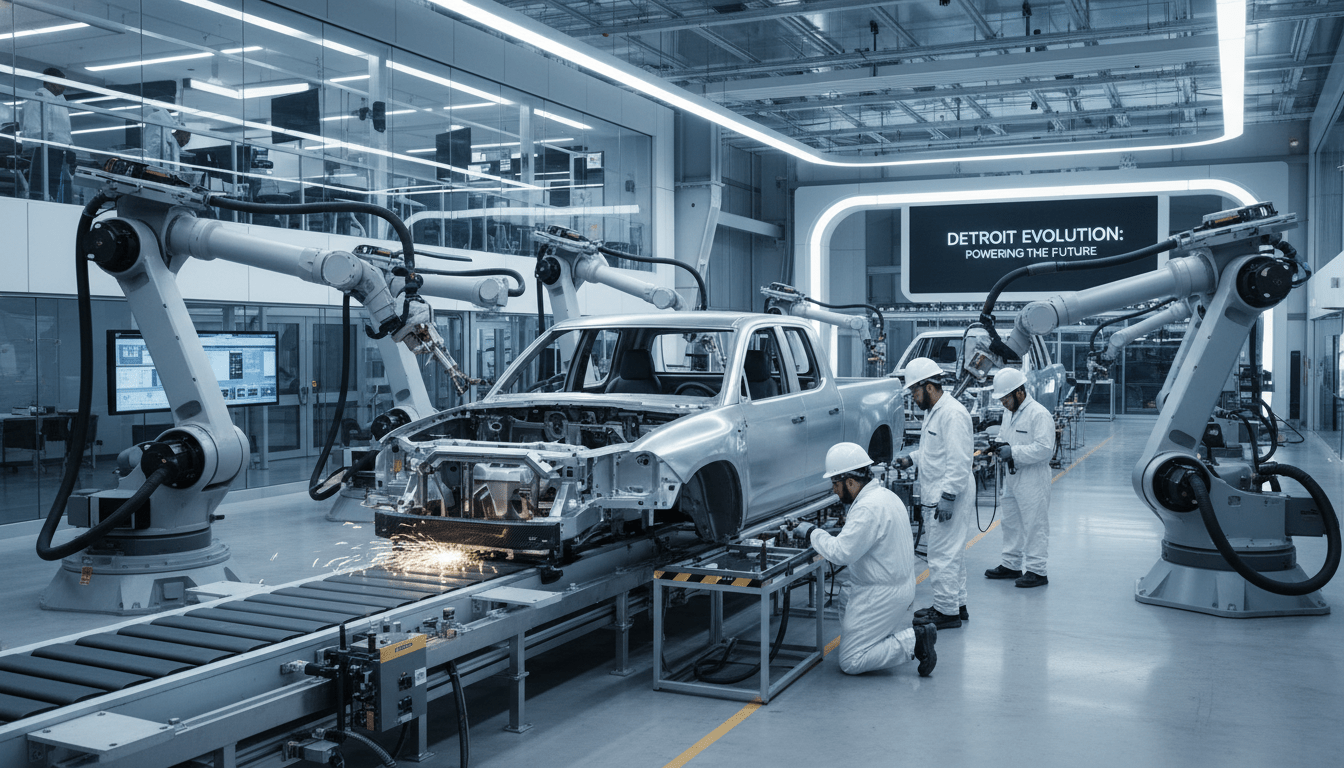

According to recent reports from the U.S. Department of Energy, Michigan remains a top contender for EV battery and vehicle production investment. In Detroit specifically, the focus has narrowed on the highly profitable truck segment. The production of the Chevrolet Silverado EV and the GMC Hummer EV Pickup at Factory ZERO represents a massive logistical overhaul of traditional assembly lines.

“The retooling required for electric truck manufacturing is unprecedented,” noted industry analyst Marcus Thorne. “We aren’t just changing engines; we are integrating complex battery platforms into vehicle architectures that need to perform as well as, if not better than, their gas-powered counterparts.”

Despite some market fluctuations in consumer demand for EVs in late 2024, Detroit automakers have maintained their long-term commitment to electrification. Manufacturers are balancing production schedules to align with current adoption rates while preparing for a projected surge in demand by 2030.

Impact on Detroit Residents

For local residents, the rise of electric truck manufacturing brings a mix of opportunity and adaptation. The most immediate impact is on the local job market. As plants retool, the skill sets required for auto workers are evolving. Traditional mechanical roles are increasingly being supplemented by positions requiring knowledge of high-voltage systems and software integration.

- Job Security: The commitment to local plants helps secure manufacturing jobs within city limits, preventing the offshoring of production.

- Training Programs: The City of Detroit, in partnership with local unions, has ramped up training initiatives to ensure the existing workforce is not left behind during this transition.

- Economic Ripple Effects: A thriving Factory ZERO supports local suppliers, logistics companies, and small businesses in the Hamtramck and Detroit areas.

However, the transition is not without anxiety. “There is always concern when the nature of the work changes,” said a representative from a local labor advocacy group. “Our goal is to ensure that the boom in electric truck manufacturing benefits the workers who built this city, not just the shareholders.”

Background & Data

The scale of investment in Detroit’s EV infrastructure is historic. General Motors invested $2.2 billion to convert the Detroit-Hamtramck assembly plant into Factory ZERO, creating an all-electric vehicle assembly plant. This facility serves as the launchpad for GM’s multi-brand EV strategy.

Data from the Southeast Michigan Council of Governments (SEMCOG) suggests that the shift to electrification could stabilize regional manufacturing employment over the next decade, provided that Detroit’s auto sector remains competitive against emerging EV startups and international competitors.

Key statistics include:

- Investment: Over $7 billion allocated to Michigan EV and battery plants since 2020.

- Employment: Thousands of workers retrained for EV assembly protocols.

- Production Goals: Targeting annual production capacities in the hundreds of thousands for electric trucks by 2026.

What Happens Next

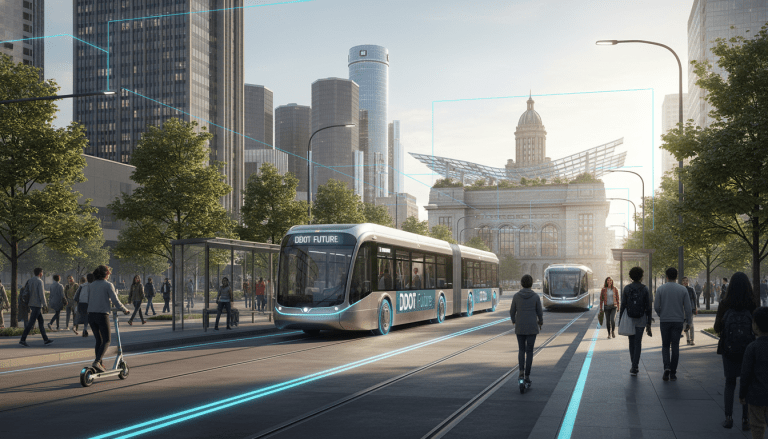

Looking ahead, the success of electric truck manufacturing in Detroit will depend on infrastructure and adoption. The city is currently working to expand charging infrastructure to support the vehicles being built in its backyard. Furthermore, automakers are working to drive down costs to make electric trucks accessible to the average contractor and family, not just luxury buyers.

As 2026 approaches, the eyes of the automotive world remain fixed on Detroit. The success of these manufacturing hubs will likely dictate the speed of the EV transition for the rest of the country.