Detroit, a city synonymous with the birth of the automotive assembly line, is once again at the forefront of a global industrial revolution. As the global manufacturing landscape shifts toward digitization and connectivity—a movement often referred to as Industry 4.0—smart factories in Detroit are rapidly transforming the local economy, altering the skyline, and redefining what it means to be a blue-collar worker in Southeast Michigan.

The transformation is visible not just in the massive retooling of legacy plants by the Big Three automakers, but also in the surge of tech-focused startups clustering around innovation districts like Corktown. This shift represents more than just a technological upgrade; it is a fundamental survival strategy for a region aiming to retain its title as the manufacturing capital of the world.

According to recent reports from the Michigan Economic Development Corporation (MEDC), the integration of artificial intelligence, robotics, and the Internet of Things (IoT) into production facilities is accelerating. These technologies are turning traditional manufacturing floors into data-driven command centers, increasing efficiency while presenting new challenges and opportunities for the local workforce.

The Rise of Smart Factories in Detroit

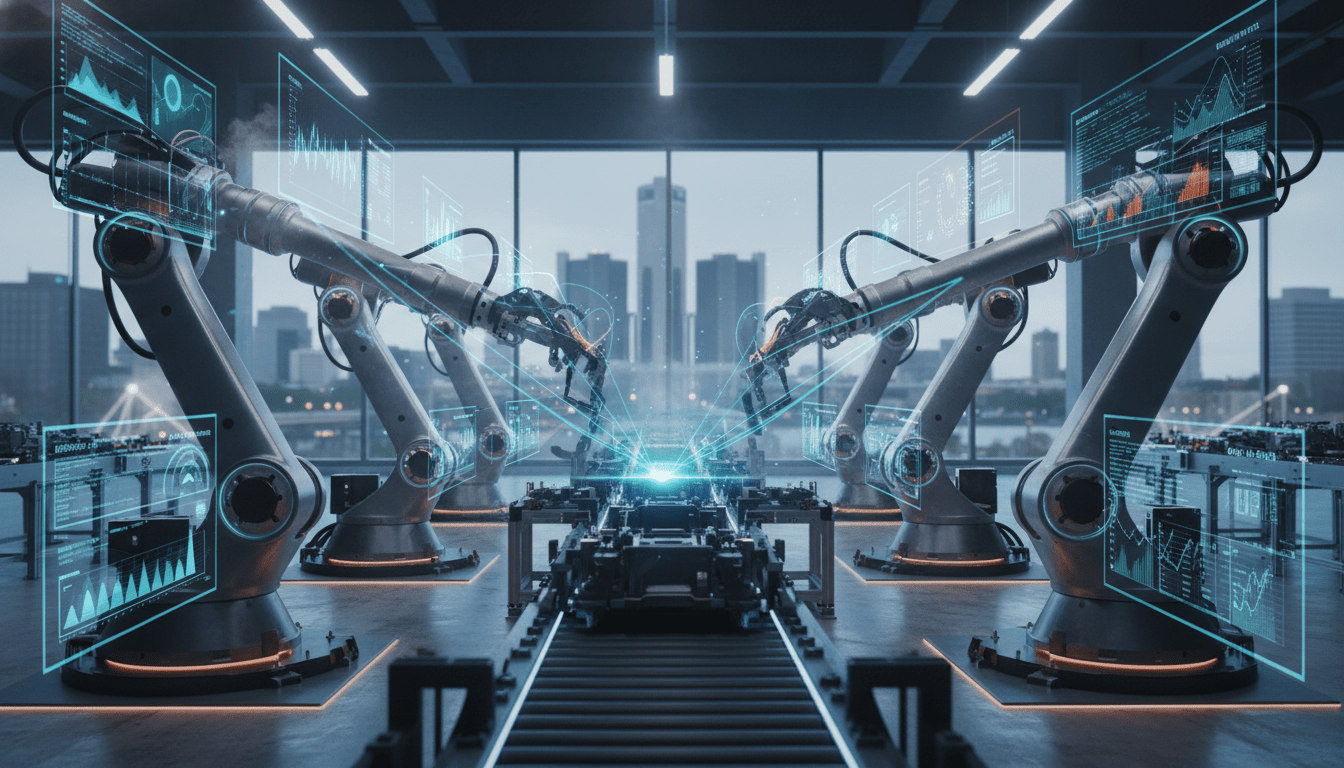

The concept of a “smart factory” goes beyond simple automation. While robots have been welding car frames for decades, the new wave of smart factories in Detroit relies on interconnected systems where machines communicate with one another in real-time. Sensors monitor equipment health to predict breakdowns before they occur, while digital twins—virtual replicas of physical systems—allow engineers to simulate production changes without stopping the line.

“We are seeing a convergence of IT and operational technology that we haven’t seen before,” said a representative from Automation Alley, Michigan’s Industry 4.0 knowledge center, during a recent industry roundtable. “Detroit is unique because we have the physical infrastructure already here. Now, we are layering the digital infrastructure on top of it.”

General Motors’ Factory ZERO, straddling the Detroit-Hamtramck border, stands as a prime example of this evolution. As the launchpad for the company’s all-electric future, the facility utilizes advanced 5G connectivity to manage thousands of distinct data points. Similarly, Ford’s Rouge Electric Vehicle Center has integrated advanced robotics that work alongside human operators, prioritizing safety and ergonomic improvements.

These developments are not limited to the automotive giants. Small and mid-sized manufacturers across Wayne County are increasingly adopting 3D printing and cloud computing to stay competitive in a supply chain that demands speed and precision. This widespread adoption signals that smart factories in Detroit are becoming the standard, not the exception.

Impact on Detroit Residents and the Workforce

For Detroit residents, the transition to high-tech manufacturing brings a complex mix of promise and pressure. The narrative that robots will replace human workers is a persistent concern, but local workforce data suggests a more nuanced reality: jobs are not necessarily disappearing, but they are changing drastically.

The demand for manual labor is gradually being supplanted by a need for technical aptitude. Positions for robotics technicians, data analysts, and systems maintainers are on the rise. This shift presents a hurdle for residents who may lack access to advanced STEM education. However, it also opens doors for higher-paying careers that do not require a four-year university degree.

“The barrier to entry is shifting,” explains a program director at a local workforce development non-profit. “You don’t need a master’s in engineering to run a CNC machine in a smart factory, but you do need specialized certification. Our focus right now is bridging that gap for Detroiters so they aren’t left behind by the very industry that built this city.”

Local organizations and community colleges are stepping up to meet this demand. Programs like LIFT (Lightweight Innovations For Tomorrow), based in Detroit, are offering training initiatives designed to upskill workers for advanced manufacturing roles. For the local economy, successful upskilling means higher median incomes and a more resilient tax base.

Background & Data: The Economics of Industry 4.0

The economic stakes of successfully implementing smart factories in Detroit are immense. Manufacturing remains the backbone of Michigan’s economy, contributing significantly to the Gross State Product. Data indicates that for every job created in advanced manufacturing, several additional jobs are created in the local service and supply sectors.

According to the World Economic Forum, which has designated several Michigan sites as “Global Lighthouses” for their leadership in Industry 4.0, facilities that fully embrace smart technologies can see productivity increases of up to 30% and significant reductions in energy consumption. This efficiency is crucial for Detroit automakers facing stiff competition from international tech companies and overseas manufacturers entering the electric vehicle space.

Furthermore, the investment is tangible. Billions of dollars have been poured into the region over the last five years specifically for retooling and technological upgrades. This influx of capital has a stabilizing effect on Detroit’s business landscape, signaling to investors that the city is a viable hub for future-tech, not just a relic of the industrial past.

What Happens Next?

Looking ahead, the evolution of manufacturing in Detroit shows no signs of slowing down. The next frontier involves the integration of Artificial Intelligence (AI) to make autonomous decisions on the factory floor, further reducing waste and optimizing logistics.

The revitalization of the Michigan Central Station by Ford is expected to serve as a magnet for mobility startups that will develop the software powering the next generation of factories. As these innovation districts mature, the symbiotic relationship between software developers and hardware manufacturers will deepen.

However, challenges remain. Cybersecurity is a growing concern; as factories become more connected, they also become more vulnerable to digital attacks. Additionally, the city must continue to address infrastructure needs, such as reliable high-speed internet and energy grid stability, to support these power-hungry facilities.

Ultimately, the rise of smart factories in Detroit is a testament to the city’s resilience. By embracing the digital age, Detroit is ensuring that the phrase “Made in Detroit” continues to carry weight in the 21st century.